LET'S TALK ABOUT 3D SCANNING |

|

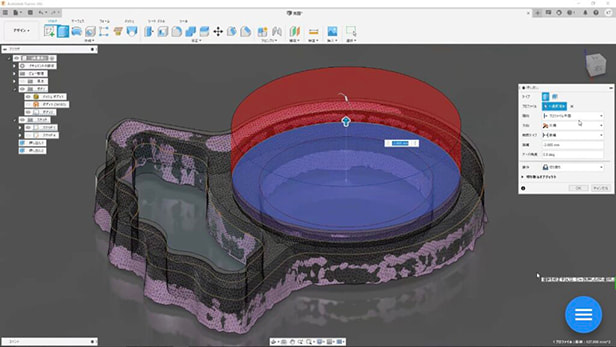

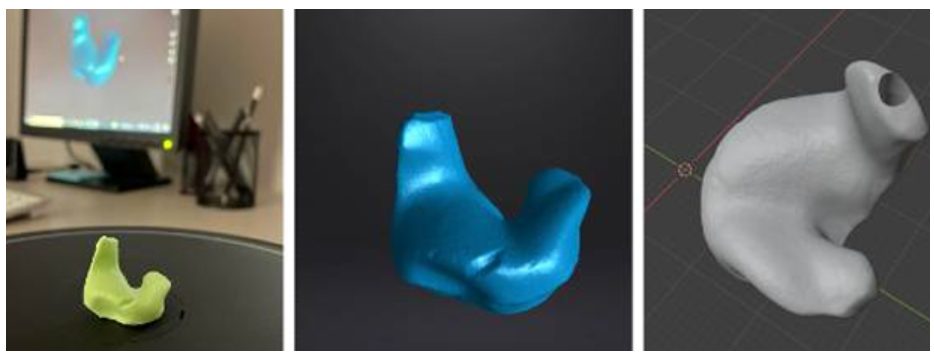

In the ever-evolving world of watersports, efoiling has taken the spotlight with its thrilling combination of surfing and flying above water. Efoil boards, propelled by electric motors, offer an exhilarating experience, and at the heart of their performance lies the efoil wing. However, this industry is young and manufacturers struggle to survive such as FOIL Inc (getfoil.com) as there is not enough demand out there leaving enthusiasts in a lurch when their favorite wing model is no longer available to purchase and the original designs may be lost. Fortunately, 3D scanning and reverse engineering offer a lifeline for reviving these designs. In this blog post, we'll explore how you can use 3D scanning technology to bring an out-of-production foil wing back to life. Importance of the Efoil Wing The efoil wing is crucial for the lift and stability of the board, directly affecting the rider's experience. Each wing model has its unique design that caters to different riding styles, water conditions, and skill levels. When a beloved wing is no longer produced, finding a suitable replacement can be challenging, making reverse engineering an appealing solution. We have 3D scanned the efoil wing 200 of the FOIL series using the EinScan Pro HD with high accuracy as the initial step to enable full reverse engineering and manufacturing. PART I: 3D SCANNNING TO CAPTURE THE ACCURATE SIZE AND CURVATURE Step 1: Preparing for 3D Scanning Before diving into the scanning process, you'll need the right tools and a suitable environment. Here is what we used.

Step 2: 3D Scanning the Efoil Wing

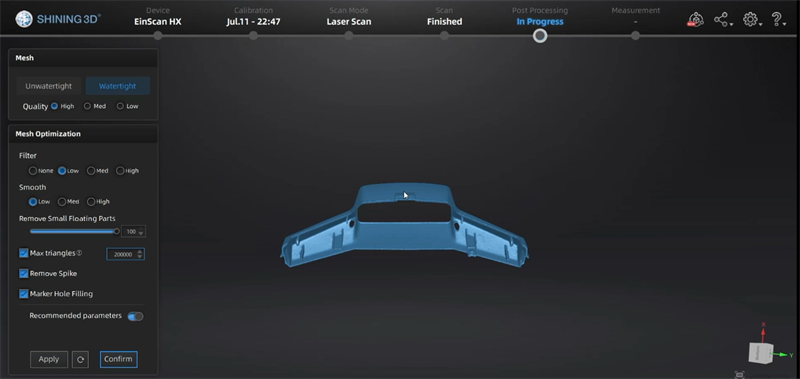

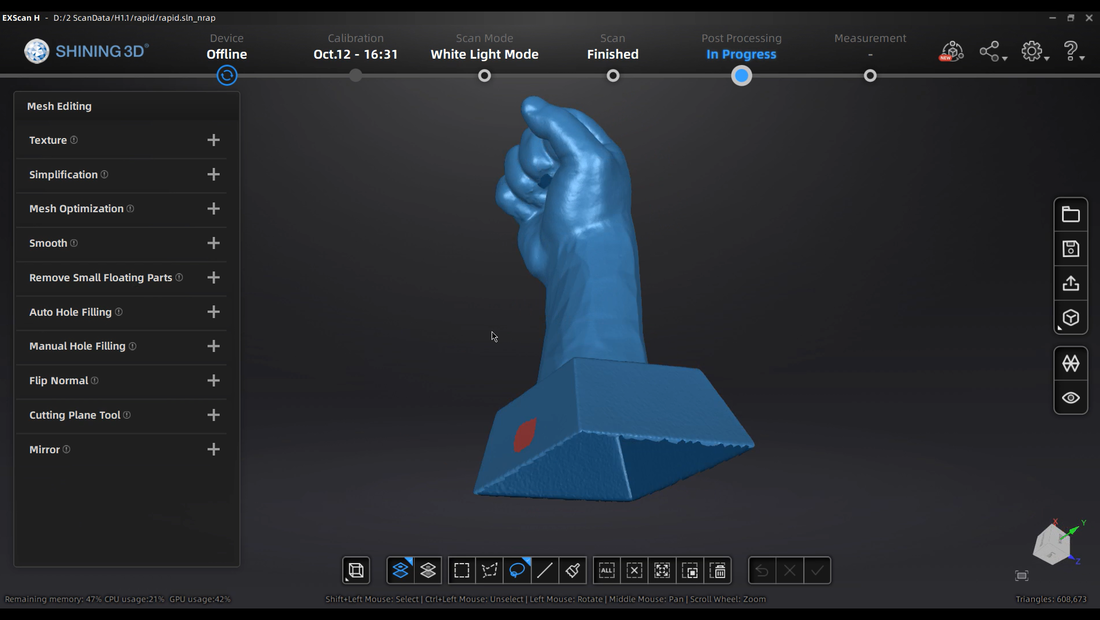

Step 3: Post Processing

Here is the STL file so you can further reverse engineer and manufacture via 3D printing!

PART II: REVERSE ENGINEERING

PART III: MANUFACTURING Once satisfied with the redesigned model, it's time to manufacture the wing.

CONCLUSION 3D scanning and reverse engineering provide a powerful combination for resurrecting discontinued efoil wings. By capturing the precise geometry of a classic wing and using modern tools to refine and replicate its design, enthusiasts can continue to enjoy their favorite efoil experiences. Whether you're an efoil aficionado or a watersports innovator, this technology opens up a world of possibilities for preserving and enhancing the sport. So, don't despair about FOIL Inc going bust, let technology breathe new life into it! Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

0 Comments

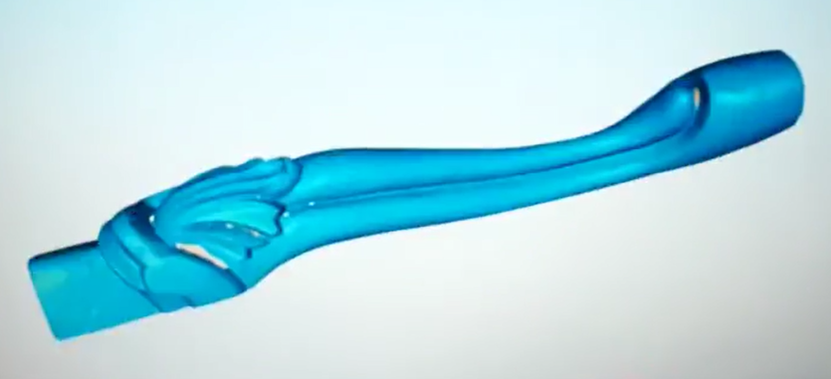

Did you know 3D scanning can help you in immensely in improving the workflow in creating various prosthetics? See below how 3D scanning will improve the fit for different parts of the body. 1. Limb Prosthetics

2. Cranial and Maxillofacial Prosthetics

3. Orthopedic Prosthetics

4. Digital Prosthetics and Bionics

5. Aesthetic Prosthetics

6. Sports and Specialty Prosthetics

7. Pediatric Prosthetics

By leveraging 3D scanning technology, the prosthetics industry can provide devices that are not only more effective and comfortable but also more accessible to a wider range of patients. This technology's ability to create highly personalized solutions is a game-changer, significantly improving the quality of life for individuals requiring prosthetic devices. Interested? Check out the below 3D scanner for best results! EinScan H2Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

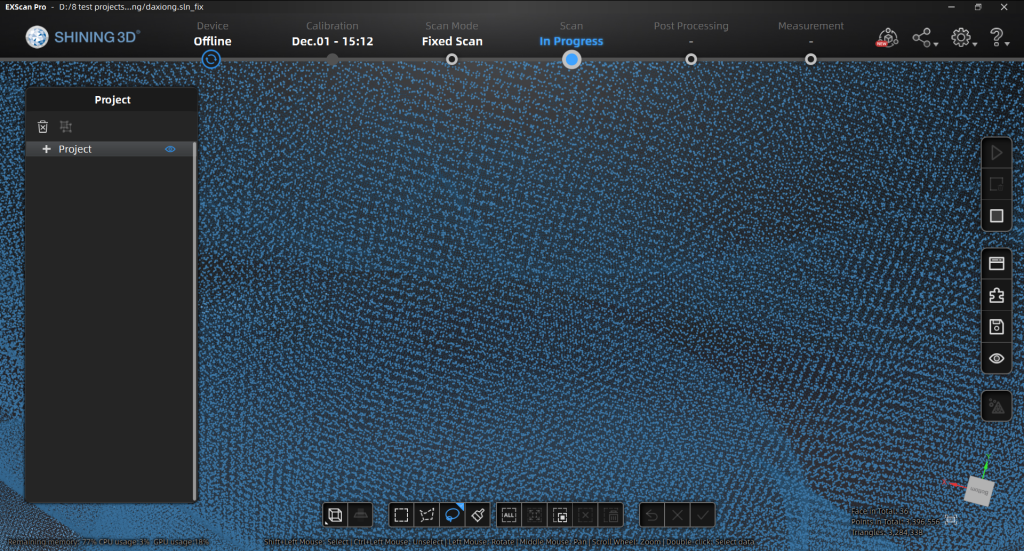

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D The new EXScan Pro V4.0 for the EinScan Pro series 3D scanners is a game-changer, delivering substantial improvements and innovative features to elevate your 3D scanning experience. From background segmentation to real-time marker recognition, automatic plane segmentation, and marker/point cloud editing, every feature is crafted to enhance precision and efficiency. The upgraded post-processing and measurement features, coupled with a user-friendly interface and additional functionalities, underscore our commitment to providing a seamless and enriched scanning experience for EinScan users. Watch the video to find out more! New Features for Fixed Scan Mode

New Features for Handheld Scan Mode

Upgraded Post Processing Features

Integration Upgrades

Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well! See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D EinScan-SE/SP V2 offers enhanced user experience compared to its predecessors and what's more now it's compatible with macOS! The 3D scanning world has been predominantly Windows compatible, but now you have the option to use with your macOS. Enhnaced 3D scanner features:

macOS compatible EXSCAN S software offers the following features.

Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D Have you ever wondered why your 3D scanner won’t capture the surface of certain objects? Or have you become frustrated by getting an incomplete 3D scan and scratching your head trying to figure out what you did wrong? Various 3D scanning technologies exist, i.e. structured light scanners, laser scanners, and photogrammetry, yet all have challenges due to the limitations of physics such as light passing through transparent objects. The surface of the object can make 3D scanning challenging. The below objects are usually challenging to 3D scan.

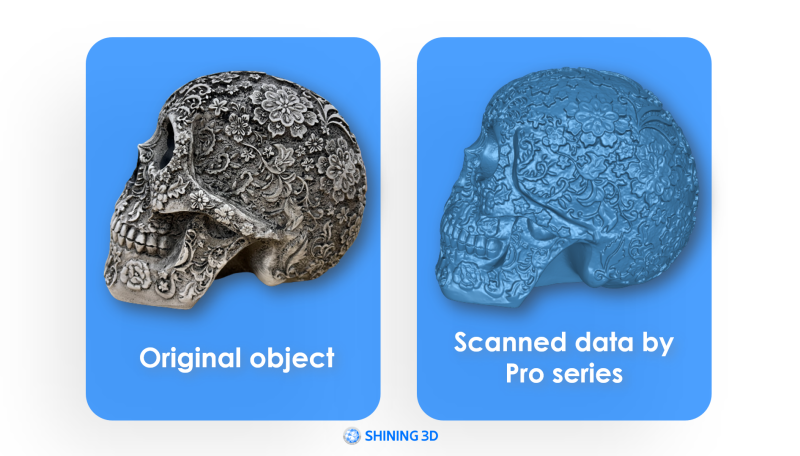

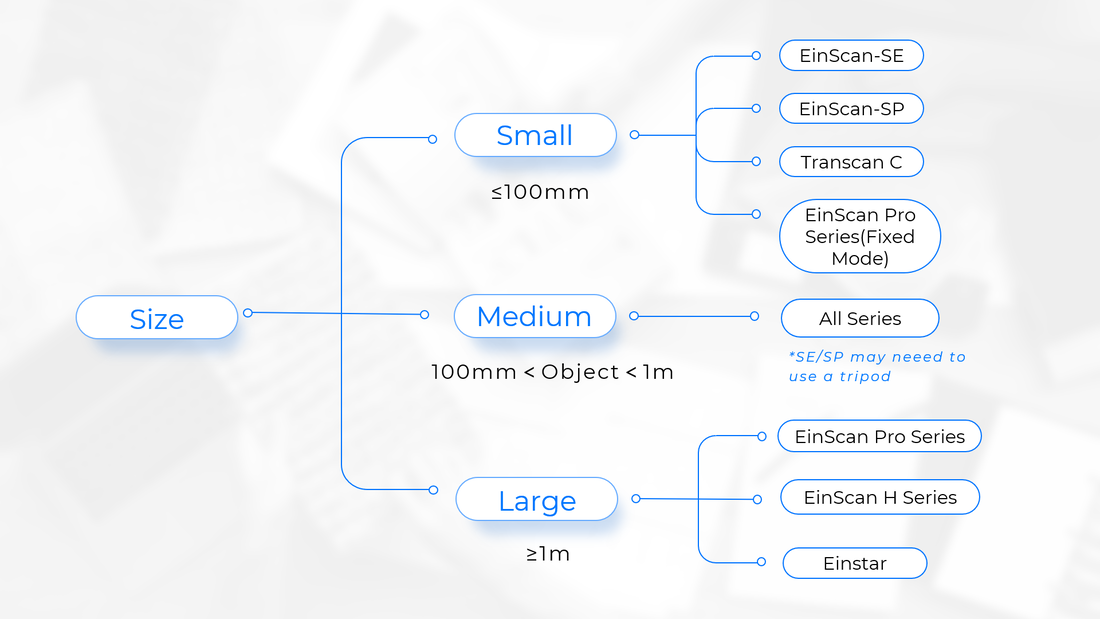

1. Highly-detailed objects When capturing highly detailed objects, it is essential to ensure that the 3D scanning parameters are adjusted to capture sharp edges and intricate details accurately for the best results. The default scan parameters may not always capture these elements with sufficient detail and high precision. However, by customizing the settings, you can obtain an accurate 3D model that faithfully represents the object without losing any important details. One crucial setting to adjust is the point distance, which determines the resolution of the scan. By selecting a smaller point distance, you can achieve a higher resolution and capture finer details even for medium-sized objects. The EinScan Pro Series multifunctional 3D scanner is an excellent choice for scanning detailed objects, offering an adjustable resolution of up to 0.2mm. With this scanner, you can reproduce intricate details with highest accuracy, ensuring a high level of precision in your 3D models captured as a .stl file. Furthermore, the EinScan Pro Series provides efficient 3D scanning capabilities and a user-friendly experience, making it an ideal solution for capturing highly detailed objects with ease. If you require a 3D scanner capable of capturing intricate details, a desktop 3D scanner would be a suitable choice. Among the recommended options are the EinScan SE, EinScan SP, Transcan C, EinScan Pro Series set up on a tripod. The Transcan C, in particular, offers an impressive resolution of up to 0.035mm, ensuring excellent detail reproduction. It's important to note that the highest resolution scans result in denser point clouds, which means more data and larger file sizes. Additionally, the software will take longer to process a greater amount of data. Therefore, it is generally recommended to use fine resolution settings for small or medium-sized objects. Scanning larger objects with a desktop 3D scanner or tripod setup can be time-consuming and labor-intensive as well. Before choosing a scanning method, consider the size of your objects. Finding the right balance between scan quality and efficiency is crucial. Assess the trade-off between the level of detail required and the time and resources available for scanning larger objects. By carefully considering these factors, you can select the most appropriate scanning method for your specific needs. 2. Dark surfaces If you've encountered difficulties in 3D scanning dark objects, you're not alone. Dark surfaces pose a common challenge in the 3D scanning process due to their high light absorption. Just like wearing a dark-colored shirt under the sun, dark colors absorb more light, which makes it difficult for 3D scanners to accurately capture their surface details. To overcome this challenge, there are a few techniques you can employ. One approach is to attach adhesive markers or targets to the object. These markers act as reference points that assist the 3D scanner in tracking and aligning the scan data. Another option is to apply white powder as simple as baby powder or Aesub Blue 3d scanning spray to the dark surface, which helps enhance the reflection of light and improve scan results. However, these methods can be time-consuming, and messy, and may not be suitable for delicate objects. Fortunately, not all light sources are created equal, and certain 3D scanners offer better performance when scanning dark surfaces. A more powerful laser and the use of blue light can be effective in capturing dark objects. Blue light has a narrower wavelength compared to white or red light, allowing for better resolution and detail capture. The EinScan HX is equipped with powerful laser lines and blue LED light in its fast mode. This combination of technologies enables efficient scanning of dark surfaces without the need for markers or white spray. In just minutes, the EinScan HX can produce high-quality scans, even for objects as challenging as a black lion sculpture. By utilizing advanced 3D scanning technologies specifically designed for dark surfaces, you can achieve accurate and detailed scans without the additional steps of applying markers or powder. 3. Reflective or shiny surfaces Scanning objects with siny and reflective surfaces present another common challenge in 3D scanning. While dark surfaces absorb light, shiny surfaces, such as mirrors or shiny metal parts, disperse and reflect light in various directions, making it difficult for 3D scanners to accurately capture the object's details. Remember how 3D scanners work. 3D scanners project light onto objects, and measure how the light is returned or deformed, but reflections make it impossible to read. In industries like machinery or automotive, shiny and metallic parts are often scanned, necessitating specific techniques to overcome this challenge. Markers and the power of the light source play crucial roles in scanning shiny surfaces. A more powerful and high-quality light source significantly improves a 3D scanner's ability to capture data from shiny objects. In some cases, especially with medium and large-sized objects, markers may be necessary to ensure excellent scanning results. Using magnet markers can provide a quick, easy, and non-destructive removal solution as well. The EinScan HX, equipped with a powerful blue laser light source and marker recognition capability, is designed to address this 3D scanning challenge. Among all the EinScan Series 3D scanners, it is the only one capable of effectively capturing shiny objects. Its advanced features enable successful scanning of metallic surfaces, as demonstrated in the example below. 4. Colorful object When scanning brightly colored objects, it is crucial to ensure accurate representation of the object's color information in the generated data for good results. This heavily relies on the pixel count or digital resolution of the texture camera used. Pixel count is typically measured in megapixels (MP), where one MP equals one thousand pixels. Insufficient camera resolution can result in color distortion and loss of detail. The good news is that all EinScan 3D scanners can capture texture data. The EinScan H and HX models come equipped with built-in color cameras, while the Pro Series offers color capture functionality through an optional color pack add-on. Different 3D scanner models offer varying camera resolutions to accommodate different budgets and specific use cases. For those seeking the highest level of color detail, the Transcan C 3D scanner is the ideal choice. It features an exclusive 12-megapixel texture camera, offering superior color detail with its higher pixel count. With the Transcan C, you can expect to capture the finest color details and achieve excellent color accuracy in your 3D scans. 5. Scanning humans When it comes to 3D scanning the human body, there are three key challenges that need to be considered: (1) maintaining stillness, (2) avoiding direct light in the eyes, and (3) successfully capturing fine details such as hair. Firstly, it is crucial for the subject to remain as still as possible during the scanning process. Even the slightest movement, such as blinking or shivering, can introduce inaccuracies in the final 3D model. Secondly, some scanners utilize intense LED lights that can be uncomfortable or temporarily impair vision if directly exposed to the eyes. This can cause discomfort and hinder the scanning experience. Lastly, capturing the intricate details of human hair presents a challenge due to its thin nature and the potential for it to blend together or appear less defined in the scan. Fortunately, specialized 3D scanners have been developed to address these specific challenges. The EinScan H2 and Einstar are excellent examples. These scanners incorporate "non-rigid" algorithms in their software that automatically compensate for slight body movements, reducing the impact of any minor shifts during scanning. Additionally, they utilize infrared rays instead of LED lights or lasers, eliminating any discomfort or vision impairment. Infrared technology proves effective at capturing both dark and light-colored hair, ensuring accurate representation of fine hair details in the resulting 3D scans. When it comes to body 3D scanning, the EinScan H and Einstar, along with their dedicated software, serve as efficient and reliable allies, helping overcome the challenges associated with scanning the human body. As you can see below, EinScan H will give you much more detail than the Einstar. Conclusion Despite the challenges posed by certain surfaces, to get the final result you want is possible by employing the right combination of hardware and software solutions. The EinScan series offers a wide range of 3D scanners designed to accommodate various situations and budgets. Each scanner within the EinScan lineup possesses unique features and specifications, making them suitable for different users and applications. Whether you're scanning complex surfaces, intricate details, or specific objects, there is an EinScan 3D scanner that fits your requirements. If you find yourself uncertain about scanning a particular surface or need guidance in selecting the most suitable scanning solution, don't hesitate to reach out to Growshapes! Our team is available to provide assistance and support to ensure you choose the optimal scanner for your needs. For those interested in delving deeper into the world of 3D scanning, we invite you to explore our webinar titled "Things You Should Know Before Buying a 3D Scanner." This webinar offers valuable insights and knowledge to help you make informed decisions. You can also refer to this blog "Which handheld 3D scanner is best for me?" We are committed to providing you with the necessary resources and support to ensure your 3D scanning endeavors are successful and tailored to your specific needs. To try before you buy, contact us too! Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

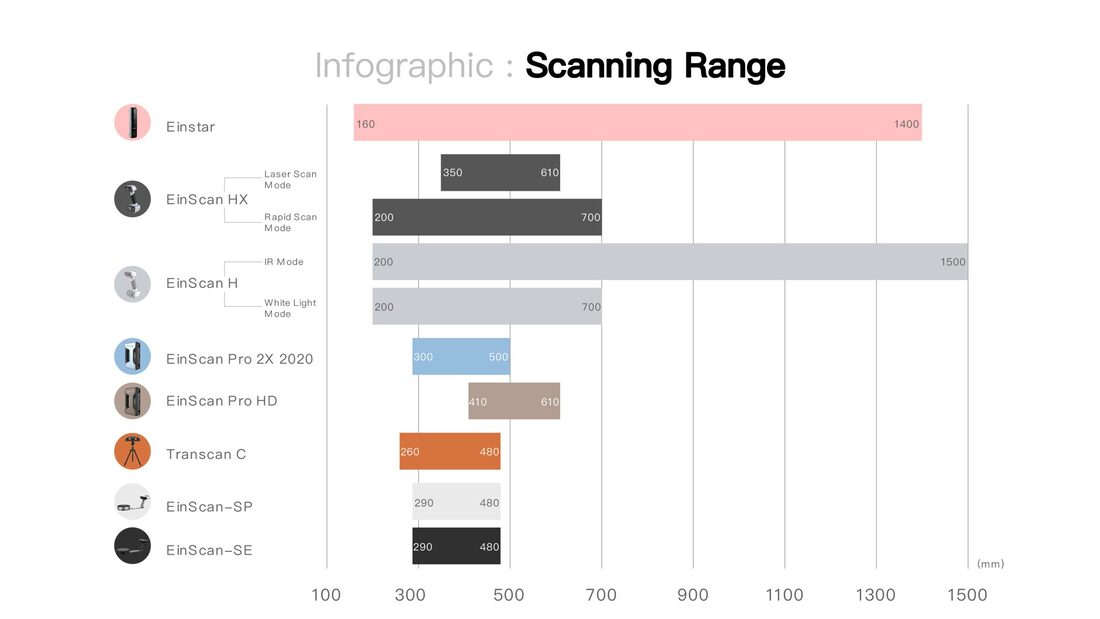

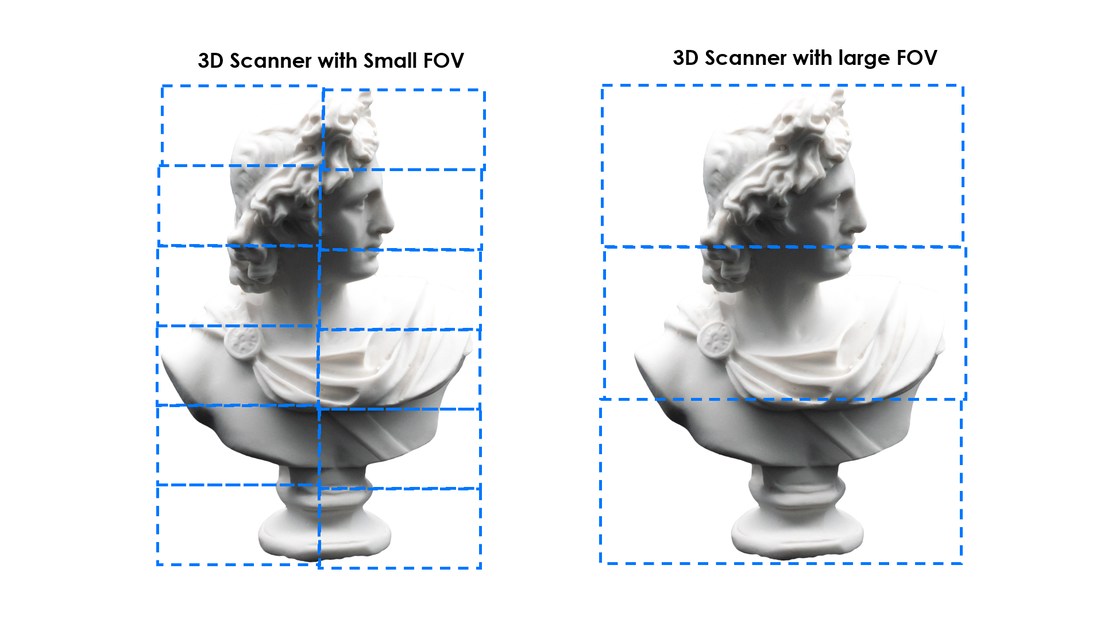

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D Every once in a while, it’s important to revisit the basics to understand how 3D scanners work. In this blog post, we’ll cover the Field of View (FOV) of a 3D scanner and how it affects the 3D scan results. The key takeaway is that different 3D scanners have different FOVs, and choosing the right model is crucial to getting the right output depending on the size of the object you want to 3D scan. What is Field of View (FOV)?Like how humans can see a certain range (you can't see behind you) at a given moment, different 3D scanners have a different viewable area at one time from a specific distance. The larger the FOV, the larger area the 3D scanner can 'see' thus capture at once. With the EinScan 3D scammer models, there is a variety of scanning range among different 3D scanner models that scan something as small as a coin to something as large as a car. Therefore, it is important to understand what you are scanning and what FOV is most suitable to capture the details of the object. The FOV of a 3D scanner can determine which model is best suited to 3D scan your object depending on its size. Choosing the right field of view is about finding the right balance between capturing enough detail of the object you want to scan and appropriate coverage for each scan. This balance is important so you can achieve a smoother scanning experience, complete scans in a shorter amount of time as well as reduce computer crashes that happen when the software is overloaded.

|

||||||||||||||||||||||||||

| What happens when you use a 3D scanner with a small FOV to scan large objects? When you scan a large object with a 3D scanner optimized for scanning small objects, you will have to do more scans to reconstruct a complete 3D digital model than you would with a scanner with a large FOV. Look at the theoretical diagram on the left. If you have a large FOV, you only need 3 scans but with a small FOV you need 12 scans. In reality there are overlaps so this is just an illustration. |

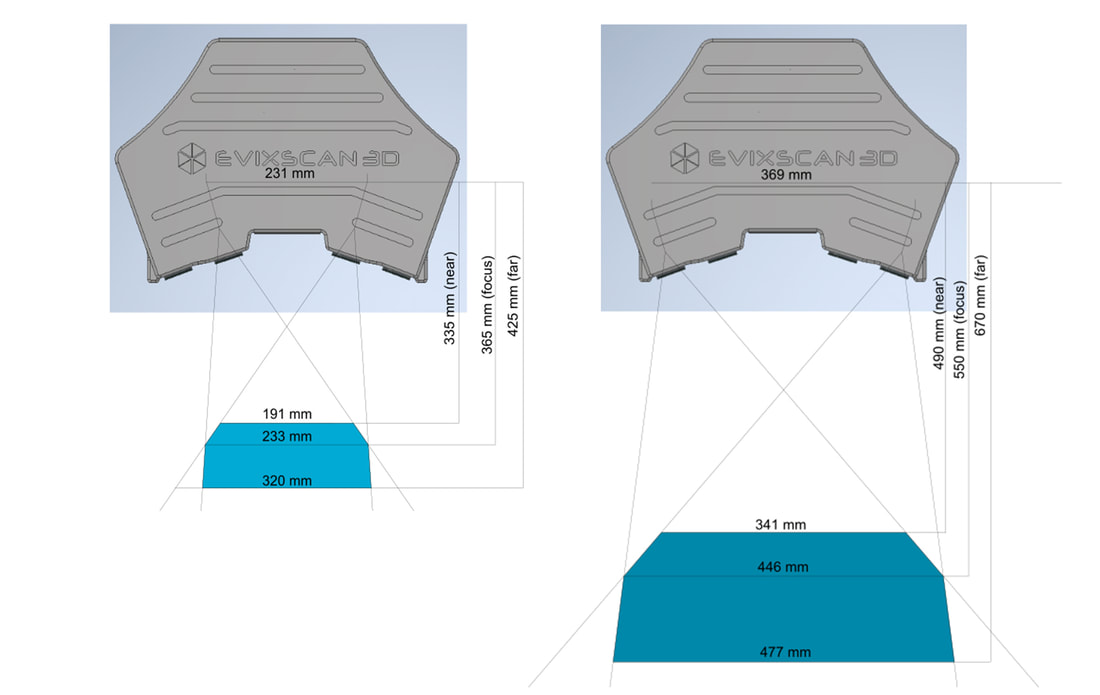

Some scanners have dual FOV like the Transcan C and the eviXscan 3D Quadro+ so it can scan small and medium size objects. On the TranScan C, you can slide the cameras out to increase the FOV, while on eviScan Quadro there are 4 cameras installed - the inner cameras and the outer cameras.

It really depends on the simplicity and versatility you require for the project. Naturally, having multiple FOV is a bit more complex due to having varying settings.

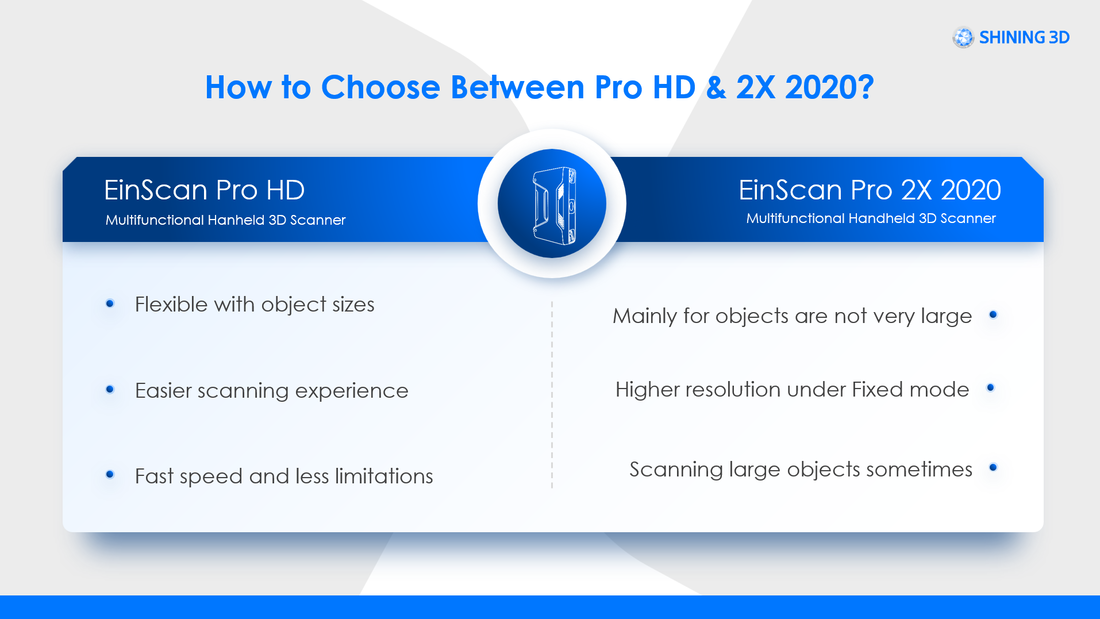

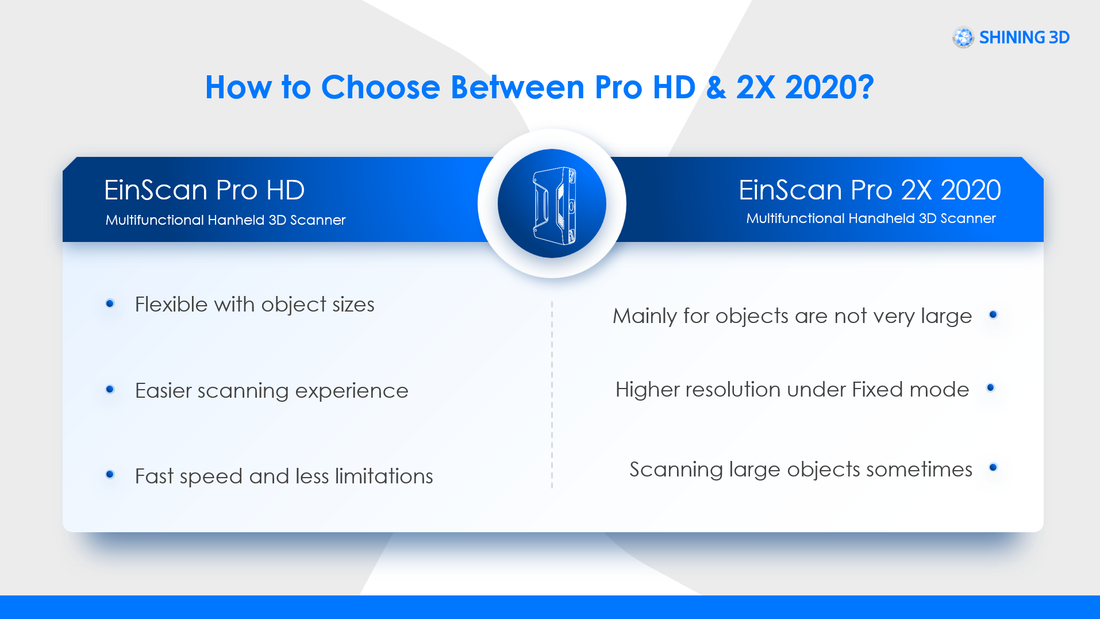

Now let's dig a little deeper and look at the difference in FOV of Einscan Pro HD vs. Einscan Pro 2X 2020.

Now let's dig a little deeper and look at the difference in FOV of Einscan Pro HD vs. Einscan Pro 2X 2020.

Comparing Einscan Pro HD vs EinScan Pro 2X 2020

You can see that these 2 scanners have a different FOV. Guess which one is better suited for large objects? You probably guessed it right if you followed the logic so far - it's the EinScan Pro HD. Objects that are not very large like within the 3-100mm range, EinScan Pro 2X 2020 is better and it's cheaper too!

So, keep in mind that there is no one-FOV-fits-all 3D scanner if you want a great 3D scanning output. The first step in choosing a 3D scanner is to confirm the size of the object you need to scan so it can help you determine the FOV of the scanner required. In the next blog, we will help you narrow it down further and together we will look at how the material on the surface of the object can affect your purchase choice.

Watch this webinar on how to select a model if you want to learn further!

Watch this webinar on how to select a model if you want to learn further!

Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

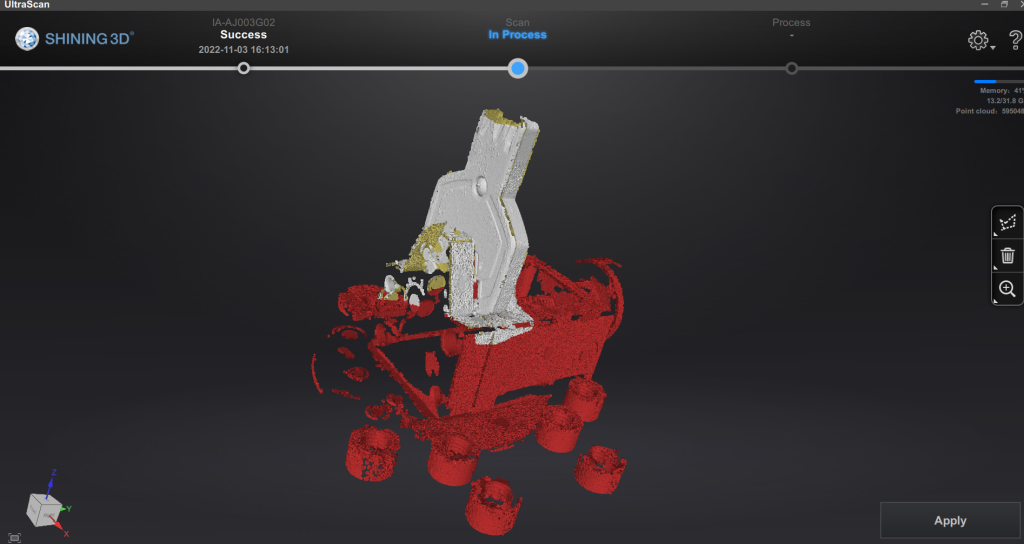

Edward Van Zyl, a seasoned 3D scanning and printing expert from Manitoba, heads the company Dreamworks 3D Printing and Scanning. With extensive expertise in vintage car restoration and customization, he is enthusiastic about utilizing state-of-the-art equipment to capture intricate details of automotive components and then utilizing software to generate accurate 3D models. This article, courtesy of Shining 3D, deep dives into the tips utilized by Edward for scanning with the EinScan HX Hybrid Light Source Handheld 3D Scanner and the reverse engineering of car parts through the use of Geomagic Essentials and Fusion 360.

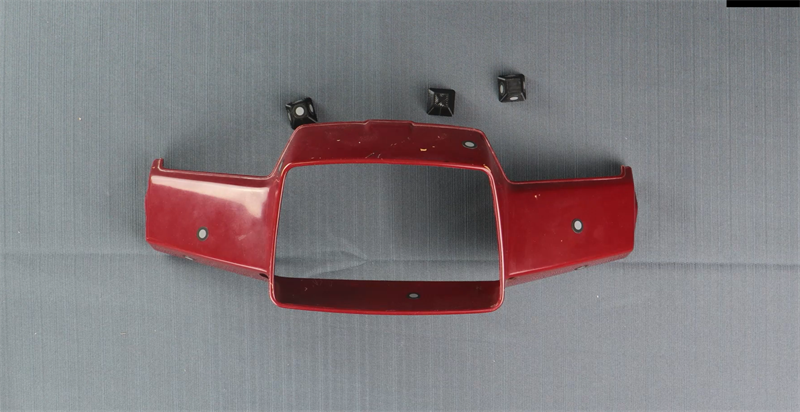

Scanning And Printing An Arrow 50 Scooter Part

Edward embarked on a projet to 3D scan and reverse engineer an Arrow 50 scooter part and then 3D print. He chose the EinScan HX Hybrid Light Source Handheld 3D Scanner for this reverse engineering project.

In the 3D scanning process, Edward provides a small tip: utilizing miniature pyramids as markers rather than some of the markers that need to be put directly onto the object. This has the advantage of saving time and cost, as it eliminates the need for post-scan cleaning and the small pyramids can be reused. You may download files of pyramids here.

Scanning And Printing An Arrow 50 Scooter Part

Edward embarked on a projet to 3D scan and reverse engineer an Arrow 50 scooter part and then 3D print. He chose the EinScan HX Hybrid Light Source Handheld 3D Scanner for this reverse engineering project.

In the 3D scanning process, Edward provides a small tip: utilizing miniature pyramids as markers rather than some of the markers that need to be put directly onto the object. This has the advantage of saving time and cost, as it eliminates the need for post-scan cleaning and the small pyramids can be reused. You may download files of pyramids here.

In laser scan mode, EinScan HX has a maximum scan speed of 480,000points/s. It just took around 12 minutes to complete the whole scan of the component. And the laser scan mode of EinScan HX makes the scanned data accurate up to 0.04mm, thus you get a very accurate model for subsequent work.

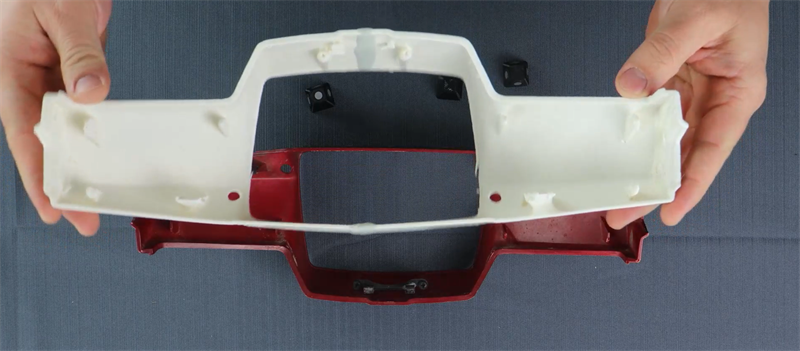

Below is the 3D printed part from Bambu Lab X1-Carbon Combo 3D Printer.

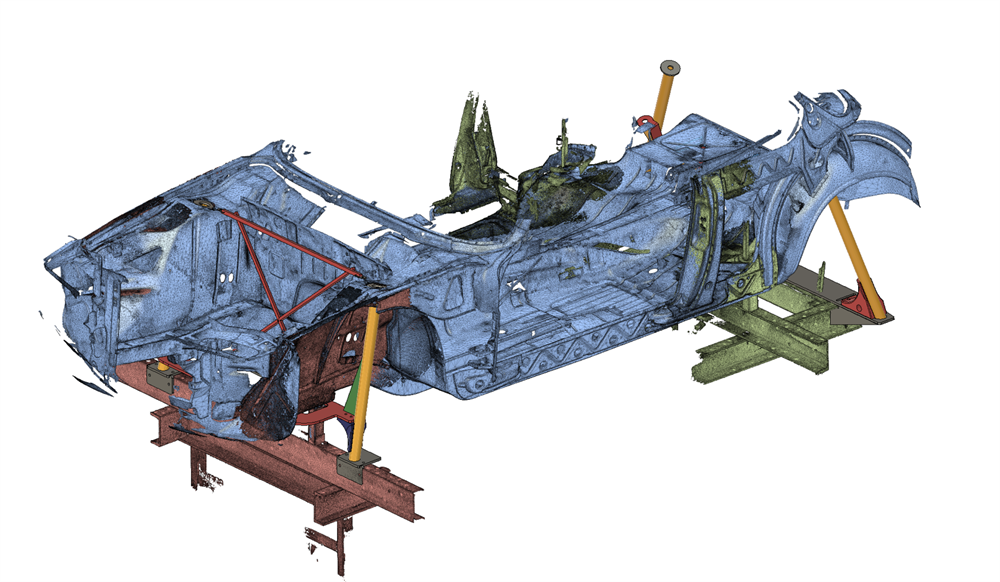

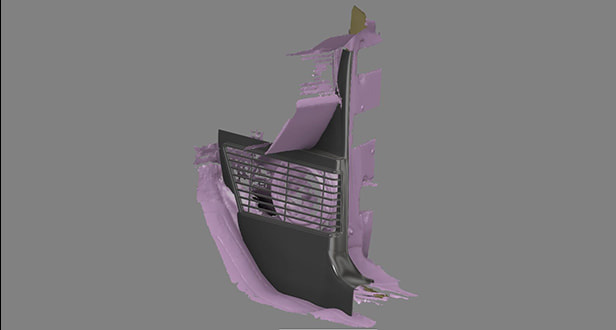

Cutting A Fender Using Geomagic Essentials

Edward’s goal was to cut a fender and make sure it was the right size for installation. Usually, he will print out the part for test, and in this case he offers an easy-to-print and material-saving trick.

He creates a small offset about 5 mm or even less, and cuts the part again, so that he gets a tiny piece of the fender, but maintains the geometry he need. 3D printing this thin piece was just as good for installation testing, and using only a minimal amount of printed material.

Edward’s goal was to cut a fender and make sure it was the right size for installation. Usually, he will print out the part for test, and in this case he offers an easy-to-print and material-saving trick.

He creates a small offset about 5 mm or even less, and cuts the part again, so that he gets a tiny piece of the fender, but maintains the geometry he need. 3D printing this thin piece was just as good for installation testing, and using only a minimal amount of printed material.

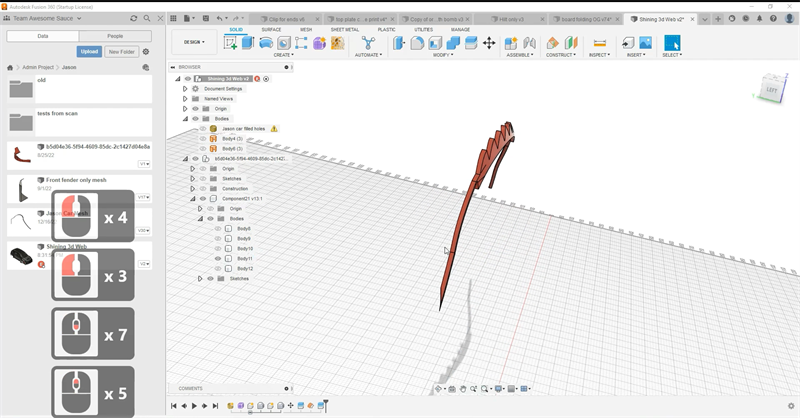

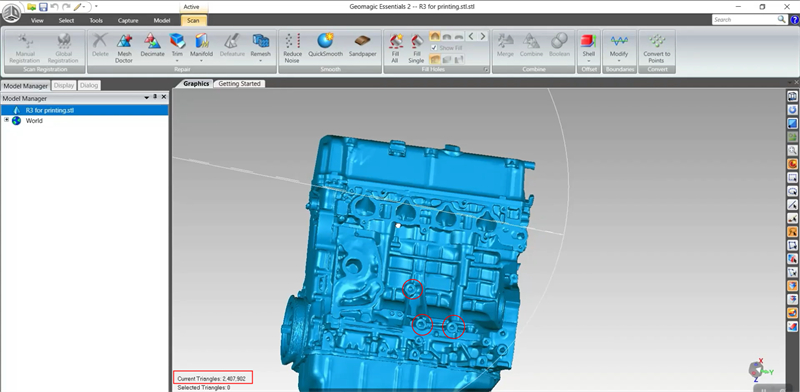

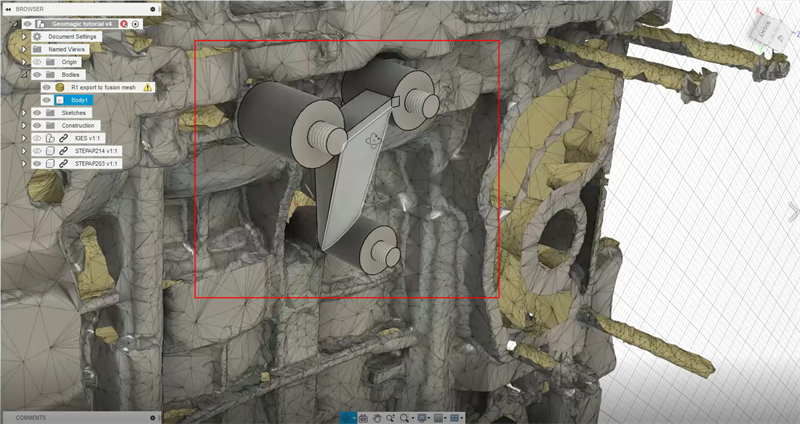

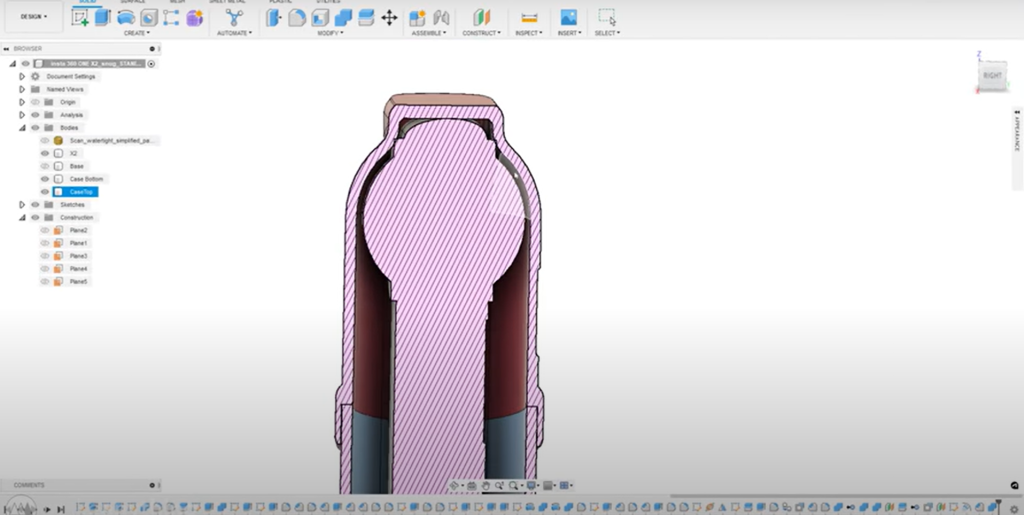

Reverse Engineering An Engine Using Geomagic Essentials And Fusion 360

Furthermore, Edward uses Geomagic Essentials to extract features on the engine, and then using Fusion 360 to model the three holes in which he wants to simulate the mounting bolts.

Furthermore, Edward uses Geomagic Essentials to extract features on the engine, and then using Fusion 360 to model the three holes in which he wants to simulate the mounting bolts.

One thing to keep in mind here is that you need to maintain the mesh and the extracted features in uniform coordinates. This step ensures that the extracted features can be overlayed on the mesh in the right position. After extruding two cylinders of different sizes and modeling some threads, the mounting bolt is done.

This is basically how to go from scanning to printing of a part; how to use a mesh and model mounting bolts in Geomagic Essentials and Fusion 360. And it is clear how much can be done with a bundle of 3D scanners and softwares.

You may find more operation details in the playback video. If you found this content useful, please follow Shining 3D's webinar pages, so you won’t miss out on more information.

You may find more operation details in the playback video. If you found this content useful, please follow Shining 3D's webinar pages, so you won’t miss out on more information.

Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

Are you still using calipers? Have you tried reverse engineering using 3D scanners? It's a new tool for an old task.

Merriam-Webster defines reverse engineering as "the process of disassembling and examining a product or device to discover the concepts involved in its manufacture, usually with the goal of producing something similar."

As the design process is beoming digitized, reverse engineering today is more commonly associated with the process of converting a physical object’s geometry into a digital 3D model and replicating the original design or further improving for new manufacturing processes such as additive manufacturing. More engineers are moving away from using calipers and adopting 3D scanners to take measurements, especially of complex parts.

Merriam-Webster defines reverse engineering as "the process of disassembling and examining a product or device to discover the concepts involved in its manufacture, usually with the goal of producing something similar."

As the design process is beoming digitized, reverse engineering today is more commonly associated with the process of converting a physical object’s geometry into a digital 3D model and replicating the original design or further improving for new manufacturing processes such as additive manufacturing. More engineers are moving away from using calipers and adopting 3D scanners to take measurements, especially of complex parts.

3D scanners allows you to digitally capture the geometry of even the most complex parts in an extraordinarily quick and precise manner. A large docking pump was recently captured in just 20 minutes for example, with the help of laser 3D scanning. This technology has enabled the use of reverse engineering in situations beyond simple benchmarking and part reproduction, as we explore in the next section.

Main Applications for 3D Scanning & Reverse Engineering

Reverse engineering with 3D scanning offers many possibilities for product development and manufacturing. Overall, the different uses of reverse engineering can be divided into three major applications: (1) to replicate parts, (2) to create variations of existing parts, or (3) to develop entirely new parts based on an existing environment or object. Let's look at each application in a bit more detail.

1. Recreate & Replicate Parts

One of the most popular uses for 3D scanners is recreating damaged or worn-out parts that are unavailable from the original supplier or lack proper documentation. This is a common problem when working with old machinery or vintage vehicles, and it’s always challenging to do with manual reverse engineering tools like calipers. However, with a good 3D scanner and the proper software, it can become a straightforward task.

Katsuya Tanabiki, for example, shared his process of reverse engineering a shield notch on an old motorcycle helmet. The helmet featured two shield notches, but one was broken, and it was too difficult to obtain a replacement notch. This tiny part was 3D scanned with an EinScan Pro 2X in Fixed Mode, and later 3D printed.

| Sometimes the actual fabrication of the part is not the end goal. In aerospace and automotive industries reverse engineering is adopted to digitize components and create digital inventories of legacy parts. These digitized components are known as “digital twins”. In generating a "digital twin', 3D scanning is indispensable to capture the intricate details of the parts with strict dimensional requirements to meet the required standards. Take for example, this small turbine reverse-engineered by Print3DD. The distinguishing geometry of its blades would be impossible to reproduce accurately without 3D scanning. |

2. Improve The Design of Existing Parts

Another goal of reverse engineering is to use digitized parts to create new and improved variants instead of merely reproducing them. This method can significantly reduce the time and costs of creating parts from scratch and also ensures a perfect fit for components belonging to larger assemblies.

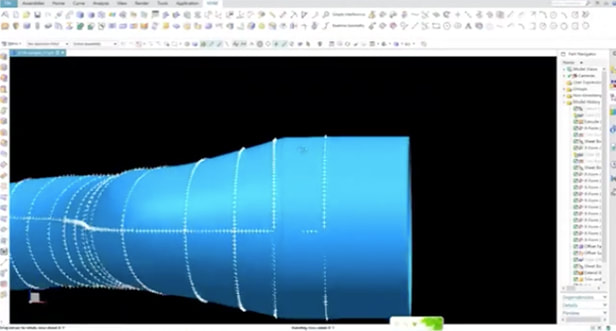

Taiwanese company Kiden Design has illustrated the reverse engineering process of optimizing a pipe using 3D scanning, CAD, and 3D printing. The EinScan Pro HD 3D scanner, used in Handheld mode, captured the irregular geometry of the pipe on two opposite sides that were stitched together later in software. Thanks to the accurate 3D model obtained, the geometry could be easily optimized in CAD.

Another goal of reverse engineering is to use digitized parts to create new and improved variants instead of merely reproducing them. This method can significantly reduce the time and costs of creating parts from scratch and also ensures a perfect fit for components belonging to larger assemblies.

Taiwanese company Kiden Design has illustrated the reverse engineering process of optimizing a pipe using 3D scanning, CAD, and 3D printing. The EinScan Pro HD 3D scanner, used in Handheld mode, captured the irregular geometry of the pipe on two opposite sides that were stitched together later in software. Thanks to the accurate 3D model obtained, the geometry could be easily optimized in CAD.

| Another good example of reverse engineering being used to create new versions of a physical objects is the customization of furniture parts with 3D scanning and CNC wood carving by Voxel 3D. In this project, the carved ornaments of one piece of furniture were digitized with 3D scanning and integrated into different parts. |

3. Create & Design Entirely New Parts

Another application for reverse engineering is where a part is digitized as a reference to create entirely new parts. This procedure is usually employed when a tight fit is required on an existing part that is too complex or has an irregular interface.

Another application for reverse engineering is where a part is digitized as a reference to create entirely new parts. This procedure is usually employed when a tight fit is required on an existing part that is too complex or has an irregular interface.

| To illustrate this, let’s look at a use case from the Fuller Moto automotive customization shop. Bryan Fuller and his team used the EinScan Pro 2X Plus to 3D scan the entire footwell of a 1967 Lincoln Continental. The digitized region was used as a reference to design a new kick panel, and the precise 3D model of the footwell made it possible for the new part to fit flawlessly in the customized car. |

This particular technique is also commonly practiced by medical professionals since body parts are unique and challenging to accurately replicate using manual methods. Here, 3D scanning once again has proven to be an efficient tool for digitizing human parts and surfaces.

Earmolds, for example, are patient-specific parts that help conduct sound from the hearing aids to the ear canal. Servicing or creating new earmolds from scratch can take several weeks during which patients experience hearing problems without them. However, thanks to reverse engineering methods with 3D scanning and 3D printing, the Hearing Beyond Audiology Clinic in Toronto can produce temporary earmolds in just one day. The temporary accessory allows patients to keep their hearing while waiting for the earmolds to be produced or serviced in other facilities. Similar reverse engineering methods with 3D scanning are also utilized for producing facial prosthetics and custom orthotics.

Quality Data Capture Is Key for Successful Reverse Engineeing

The use cases above clearly demonstrate the central role of 3D scanning in reverse engineering. It comes as no surprise that the effectiveness and accuracy of data captured by 3D scanning are crucial for a successful reverse engineering process. Yet, the software tools used for processing the data and working with the 3D models are also essential for achieving the desired results in reverse engineering. To understand the importance of good data and adequate software, let’s go over the main steps of reverse engineering with 3D scanning.

Step 1. Data acquisition

The very first step in any reverse engineering process is data acquisition. Regardless of the method, proper planning and preparation can make the difference between good and poor data. With 3D scanning, this involves selecting the correct device for the job, including the proper configuration (handheld or stationary) and accessories such as turntables, fixtures, and calibration panels. Correct calibration of the device is also vital to acquire quality data.

The regions or parts to be digitized usually demand some kind of preparation. Besides a good cleaning, some 3D scanning devices also require the use of markers or even special coatings on reflective surfaces. One should also consider the ambient conditions before starting the digitization process. A controlled environment (e.g. indoors, without direct sunlight, a cleared tabletop, …) is always preferred to reduce noise in the data, but that’s not always possible. All the factors mentioned will contribute to proper data collection, which will in turn determine how quickly and easily the data can be processed next.

Step 2. Post-Processing

The next step in a reverse engineering process is post-processing the acquired data, or the “point cloud”. Here, the point cloud is processed by software tools – like EinScan software – resulting in a 3D mesh representation of the digitized object.

The very first step in any reverse engineering process is data acquisition. Regardless of the method, proper planning and preparation can make the difference between good and poor data. With 3D scanning, this involves selecting the correct device for the job, including the proper configuration (handheld or stationary) and accessories such as turntables, fixtures, and calibration panels. Correct calibration of the device is also vital to acquire quality data.

The regions or parts to be digitized usually demand some kind of preparation. Besides a good cleaning, some 3D scanning devices also require the use of markers or even special coatings on reflective surfaces. One should also consider the ambient conditions before starting the digitization process. A controlled environment (e.g. indoors, without direct sunlight, a cleared tabletop, …) is always preferred to reduce noise in the data, but that’s not always possible. All the factors mentioned will contribute to proper data collection, which will in turn determine how quickly and easily the data can be processed next.

Step 2. Post-Processing

The next step in a reverse engineering process is post-processing the acquired data, or the “point cloud”. Here, the point cloud is processed by software tools – like EinScan software – resulting in a 3D mesh representation of the digitized object.

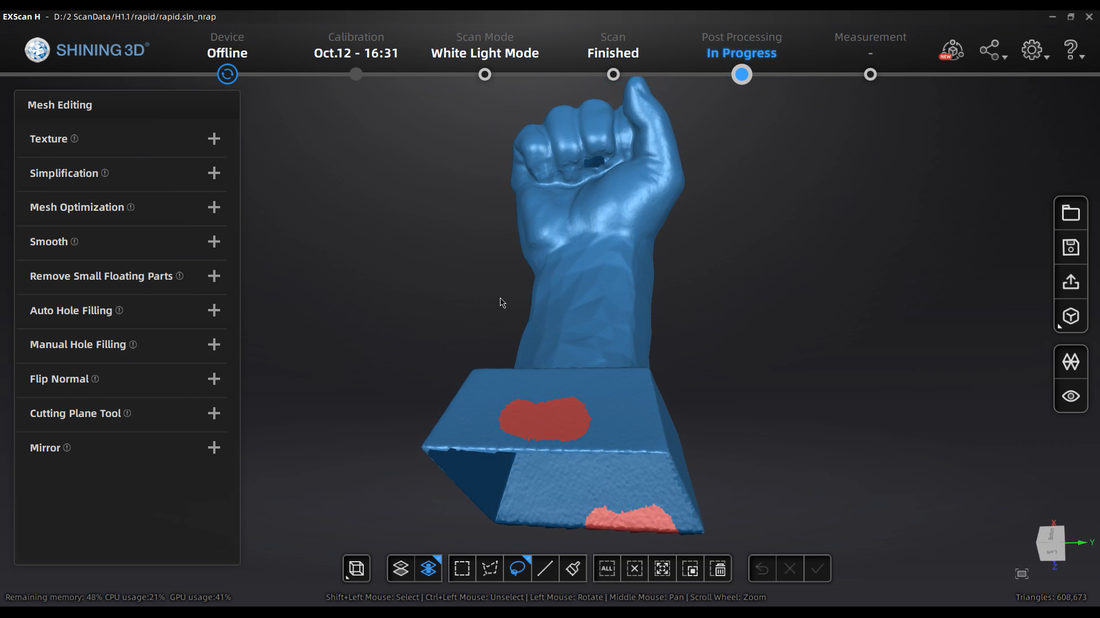

In any case, the 3D model in this initial stage usually requires some refinement like removing unwanted captured data, repairing surfaces, and filling gaps per below.

The better the data quality acquired, the less post-processing and repairing will be needed. The post-processing step is also when reference entities are assigned to the 3D model, a procedure that should expedite the next stage of the reverse engineering process.

Step 3. CAD Model Generation

The final step in a reverse engineering process is to convert the mesh representation of the physical object captured by the 3D scanner into a solid 3D model.

As accurate as the mesh model can be, it is inadequate for most reverse engineering applications that require additional handling like fixing any physical damage, creating variations, or designing new parts altogether. In this stage, the refined mesh model from the previous step works as an exact reference model for recreating the model using parametric CAD tools.

Although in theory any general-purpose CAD program could handle this, specially purposed software geared towards reverse engineering can make the process much easier and yield much better results too.

An appropriate CAD software for reverse engineering can also compare the digitized model to the parametric one, allowing users to check for geometrical and dimensional differences.

Conclusion

Reverse engineering has come a long way and 3D scanning technologies have broadened the range of industrial applications for reverse engineering, benefiting both businesses and consumers.

The quality of the captured data is crucial to obtain good results in reverse engineering. The choice of the 3D scanning device, as well as its capabilities and functions, play a central role in the success of the entire process. Read further about how to make sure you choose the right model for your project here.

Though often overlooked or underestimated, the software used in the later stages of reverse engineering also bears great importance. Specific built-in tools for the job can make a big difference in a well-executed reverse engineering process.

Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

You know what's great about EinScan 3D Scanners? The software that comes with the 3D scanner is a perpetual license which means no additional fees for software upgrades and Shining3D keeps improving its software as it develops new features!

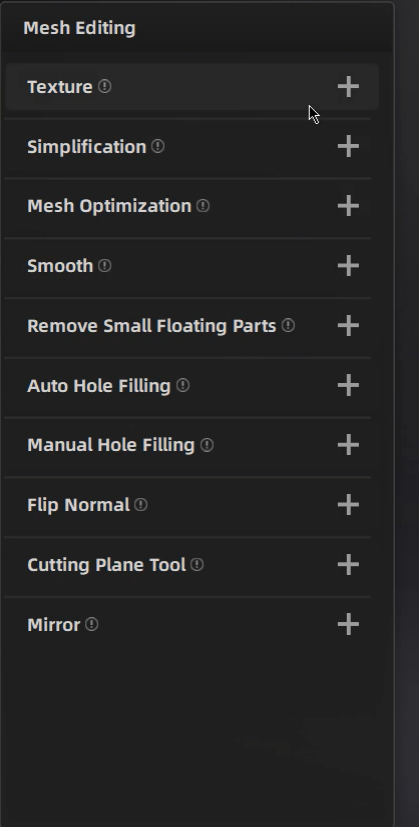

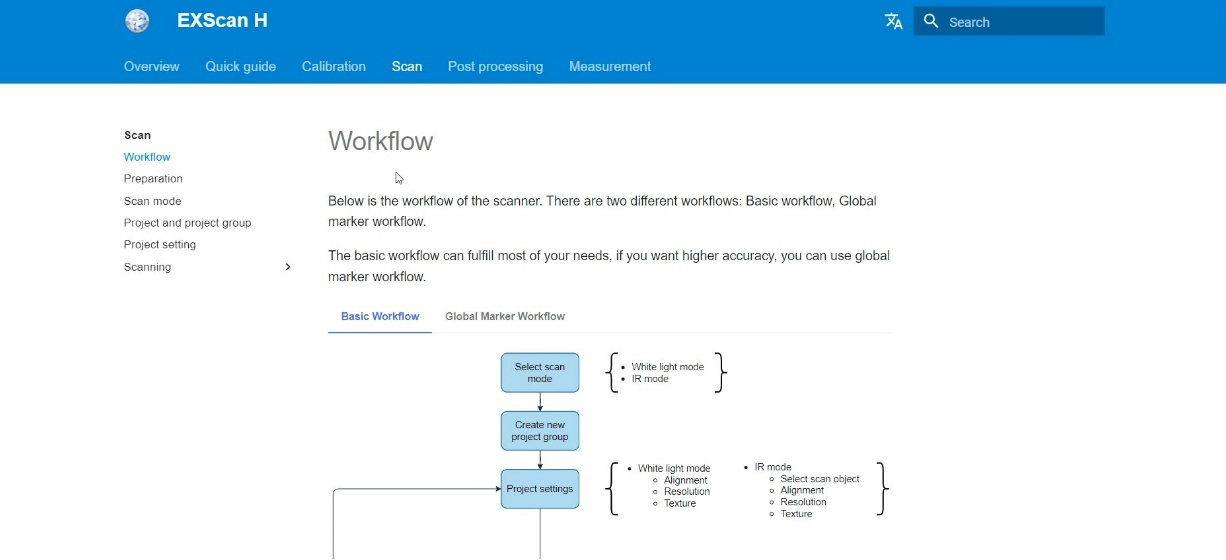

This time, the new software update is for EinScan H. Let dive right into some of the updates:

Before we get into the details of these updates, please note that the projects saved by previous versions are not compatible to this new released version. Please make sure you have finished all your projects in previous versions and then update to this new version!

Now onto the key improvements in more detail!

This time, the new software update is for EinScan H. Let dive right into some of the updates:

- Changed the scan mode names to “white light scan mode” and “IR scan mode” for clarity

- Added scanning setting functions: working distance adjustment and data quality indicator function are now integrated

- Added new selecting tools for editing, like line, rectangular box

- Made “cloud points optimization“ available as option

- Added more meshing parameter settings

- Added rich post-processing function

- Added project information display

- Modified the calibration prompt information

- Improved the style of file explorer

- Provided online user manual

- Added Shining 3D User Account

Before we get into the details of these updates, please note that the projects saved by previous versions are not compatible to this new released version. Please make sure you have finished all your projects in previous versions and then update to this new version!

Now onto the key improvements in more detail!

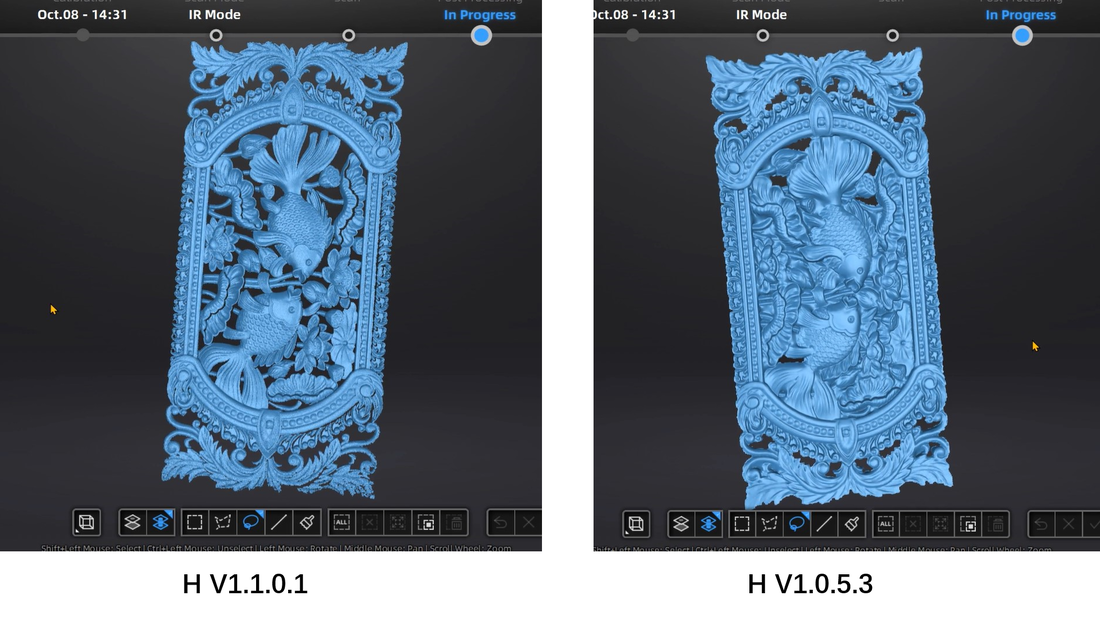

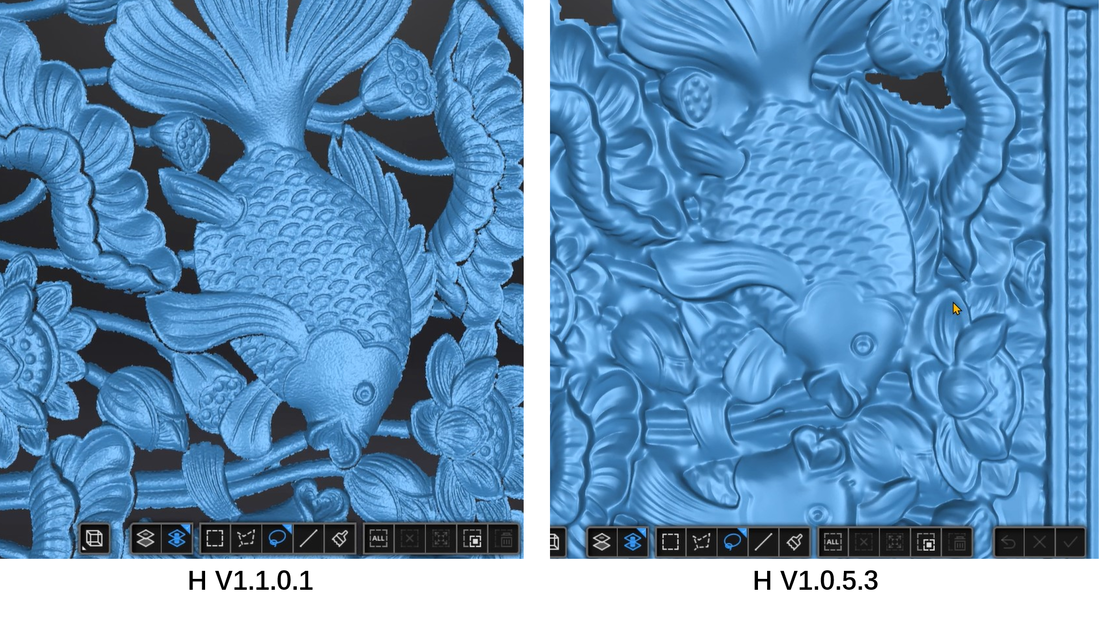

IR Mode Data Quality Improvment

IR Mode (Infrared Ray Mode) uses an invisible light source thus suited for scanning people and slightly reflective objects. Data quality and accuracy are lower that in white light mode but with the new update of V1.1.0.1, captured data quality has significantly improved in IR mode.

IR Mode (Infrared Ray Mode) uses an invisible light source thus suited for scanning people and slightly reflective objects. Data quality and accuracy are lower that in white light mode but with the new update of V1.1.0.1, captured data quality has significantly improved in IR mode.

Look more closely and you'll see massive improvement.

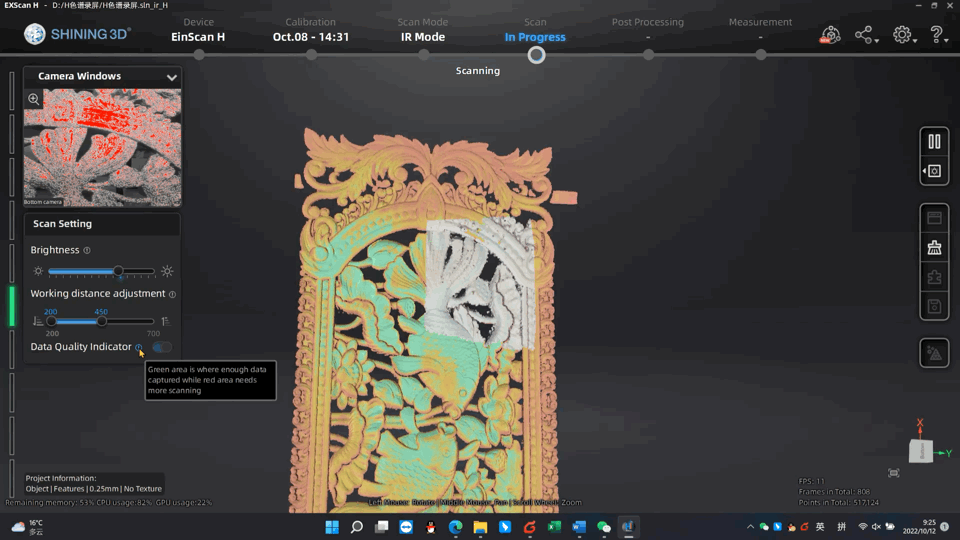

Data Quality Indicator Function

The updated HV1.1.0.1 has a new data quality indicator tool to help you get better data. The red color represents the insufficient data amount, the yellow color represents the imcomplete data amount, and the green color represents the adequate data amount so easy to see if you have captured sufficent data while you are scanning. This is implemented in the Einstar too.

The updated HV1.1.0.1 has a new data quality indicator tool to help you get better data. The red color represents the insufficient data amount, the yellow color represents the imcomplete data amount, and the green color represents the adequate data amount so easy to see if you have captured sufficent data while you are scanning. This is implemented in the Einstar too.

Mesh Select Tool:Select Through / Visible

A new functional selection tool has been added to the post processing session. You can now select either a through or a visible point cloud.

More Mesh Parameters

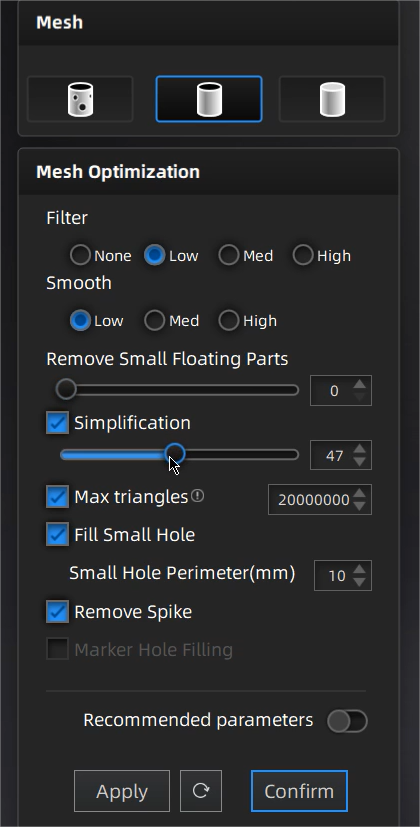

Compared to previous versions of the software, this update provides significant improvements to the mesh parameters, offering a wide range of options to choose from.

Free to Select Point Cloud Optimization

This update allows users to freely choose whether to perform point cloud optimization or not. Take the sample part on the figure as an example, generating the point cloud directly takes about 50%* less time than generating the point cloud after optimization. You can choose whether you want to generate the point cloud after optimization according to your needs.

Online user manual

You can visit our online user manual for more instructions on how to use the product. Click on the image below to download the manual.

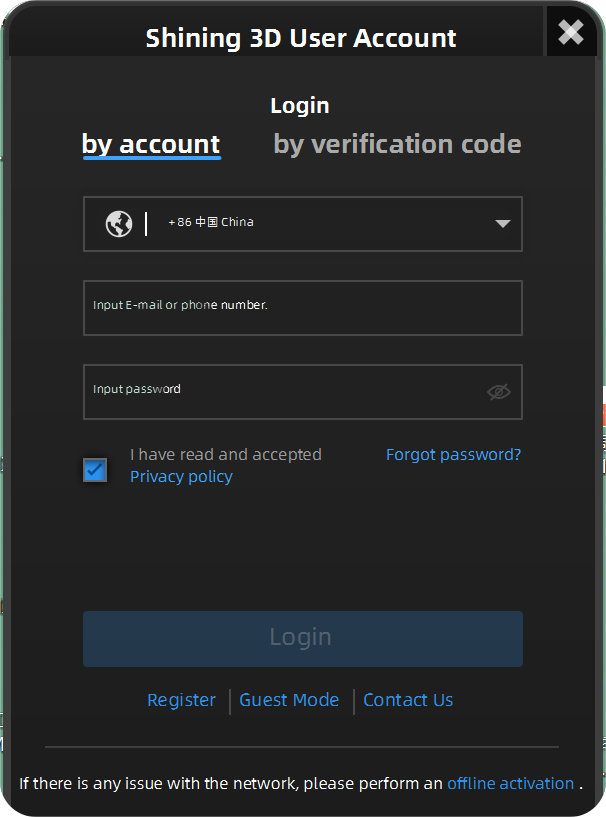

Shining Account Integration

This update adds a new Shining account login page where you can register your account and jump to our cloud-based platform where you can make software updates, download product manuals, learn about Shining 3D products, and more. In addition, with this update you will be able to activate the software online and offline.

These are all the updates and below is the link!

Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

Shining 3D has come out with an affordable 3D scanner to enable 3D scanners to be used by more people to digitize our world in full color! Best suited for VR/AR applications and digital content designers for sure.

It's pretty good for a low cost 3D scanner, but ofcourse if you want more accuracy you do need to step up a notch for the higher end models.

Check out the video we created below.

It's pretty good for a low cost 3D scanner, but ofcourse if you want more accuracy you do need to step up a notch for the higher end models.

Check out the video we created below.

Also beware you do require a good GPU and lots of memory to run this 3D scanner.

Einstar

Generates high-quality 3D data in full color at an affordable price and easy to use software. Perpetual license with no ongoing subscription fees.

Approx. 0.3mm accuracy.

PC Requirement: Win 10/11 |32GB RAM | NVIDIA GTX or RTX with over 1,000 CUDA cores | Intel CPU i7 or i9

Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

Growshapes

Provider of leading edge 3D scanning products and services. We see 3D!

Archives

July 2024

June 2024

May 2024

March 2024

December 2023

October 2023

June 2023

April 2023

February 2023

October 2022

September 2022

August 2022

May 2022

April 2022

March 2022

February 2022

November 2021

October 2021

August 2021

April 2021

March 2021

January 2021

December 2020

November 2020

September 2020

August 2020

June 2020

April 2020

March 2020

January 2020

December 2019

November 2019

October 2019

June 2019

May 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

November 2017

October 2017

September 2017

August 2017

July 2017

April 2017

February 2017

January 2017

December 2016

November 2016

October 2016

July 2016

June 2016

May 2016

April 2016

January 2016

December 2015

November 2015

October 2015

September 2015

July 2015

June 2015

April 2015

March 2015

January 2015

December 2014

November 2014

October 2014

September 2014

August 2014

July 2014

June 2014

May 2014

April 2014

March 2014

February 2014

January 2014

Categories

All

3D Printing

3D Scan File Ouput

3D Scanner Rental

3D Scanner Setup

3D Scanning

3D Scanning Colorful Objects

3D Scanning Dark Surfaces

3D Scanning Faces

3D Scanning Highly Details Objects

3D Scanning Humans

3D Scanning Large Objects

3D Scanning Shiny Surfaces

3D Scanning Small Objects

3D Visualization

Additive Manufacturing

Afinia

Alignment In 3D Scanning

Augumented Reality (AR)

Blue Laser

Blue Light

DAVID 3D Scanners

Design

Desktop 3D Printers

Ecology/Sustainable

Education

EFoil Wing

EinScan 3D Scanners

EinScan 3D Scanner Software

Einscan H

EinScan H2

EinScan HX

EinScan Pro 2X

EinScan Pro 2X 2020

EinScan Pro 2X Plus

EinScan Pro HD

EinScan SE/SP

Einstar

Engineering

Evatronix EviXscan

Field Of View

FormLabs

Geomagic

HP Structured Light Scanner Pro S3

Industrial Kit

Infrared

Laser 3D Scanning

MacOS

Makerbot

Makerspace

Market SIze

Mcor IRIS 3D Printer

Medical

Mesh Optimization

Netfabb Software

Open Technologies Cronos 3D Scanner

Orthotics And Prosthetics

Product Developers

Prototyping

Reverse Engineering

Shining3D

Software Updates

Solid Edge Software

Structured Light 3D Scanning

Transcan C

White Light

Workforce Development

|

Vertical Divider

GROWSHAPESStay connected |

Menu |

©2024 Growshapes LLC. All rights reserved.

RSS Feed

RSS Feed