LET'S TALK ABOUT 3D SCANNING |

|

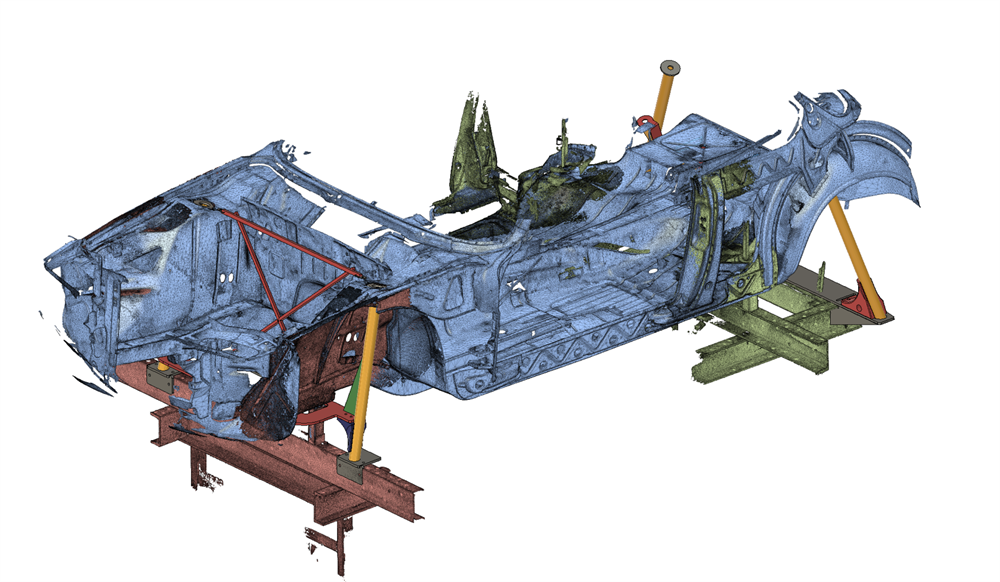

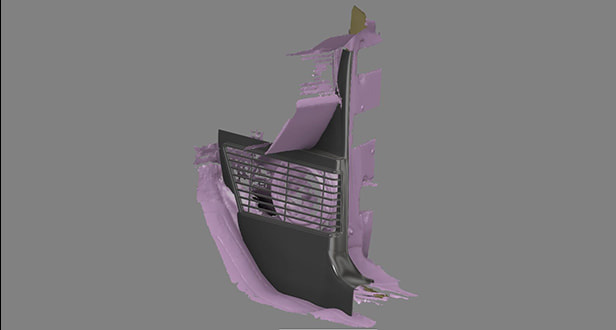

With over 35 years of business experience and an extensive history working on Ferrari vehicles, Italian Design and Racing, based in Mesa, Arizona, is a custom fabrication and restoration company that specializes in Italian exotic cars. Their engineering team is using the EinScan HX Handheld 3D scanner to preserve a vintage racing car body which was placed on a more modern Ferrari chassis. Chris Carpenter, lead technology engineer, talked about his experience with 3D technology and how the hybrid light source 3D scanner, EinScan HX completely changed their workflow. After a crash destroyed the original Ferrari 750 Monza Spyder body, an aspiring young car builder, Peter Monteverdi (a Swiss car maker and creator of the car brand Montiverdi) designed the first gullwinged door body to be used on a Ferrari chassis, which at the time was built by Sauter out of Switzerland in 1957. The gullwing body had been kept by private collectors off of its original chassis. “We’re looking to restore the car body”, says Carpenter. “We’ve adapted a more modern Ferrari chassis and drive train to restore its bespoke look.” Carpenter joining the team has shifted its restoration process from analog to digital, with EinScan HX Handheld 3D scanner being a key tool to digitize the parts for restoration projects. Advantages of Hybrid Light Source 3D Scanner Since the EinScan HX Handheld 3D scanner can scan by features or markers, it has the flexibility to scan objects of any size. Restorers not only need to scan the body and chassis to find the right installation point, but also need to scan various sizes and shapes of parts. Even a small error or misalignment can skew the assembly of the doors and chassis, therefore being able to 3D scan different parts efficientlyis key. The laser is less sensitive to ambient light and performs better on reflective surfaces such as body panels, while the blue LED light allows for a rapid scan mode, quickly providing more interior and engine compartment data to test fit parts and better understand the clearance of custom parts. The combination of two light sources saves working time and improves efficiency. Significance of 3D Scanning Results The scanning data will have long-term consequences for the field of racing car restoration. The scans can be used by fabricators as a reference to assist in recreating the car’s original shape, saving time and resources in the event of damage done to the vehicle. It may also be used for additive manufacturing, through reverse design and 3D printing to make parts that are no longer in production or hard to find. Read this blog about how a hobbyist created some parts for his old Mini Cooper here too! Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

1 Comment

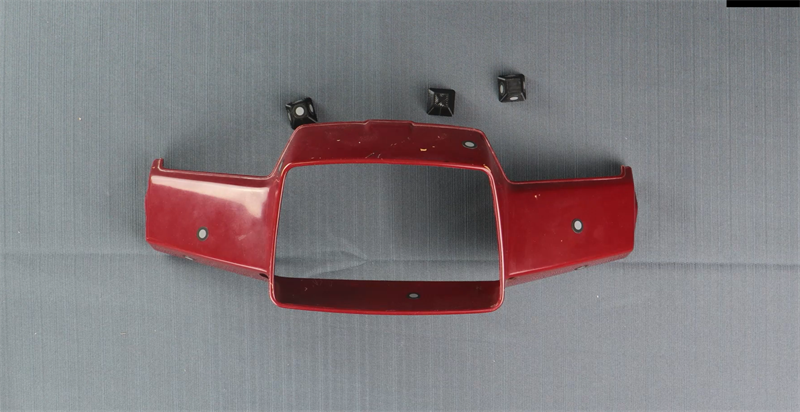

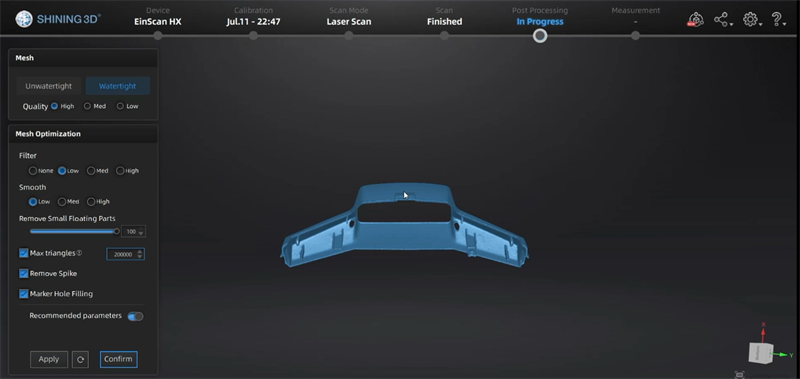

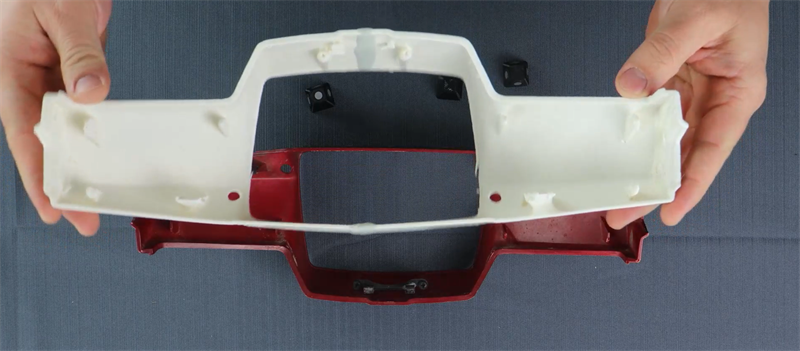

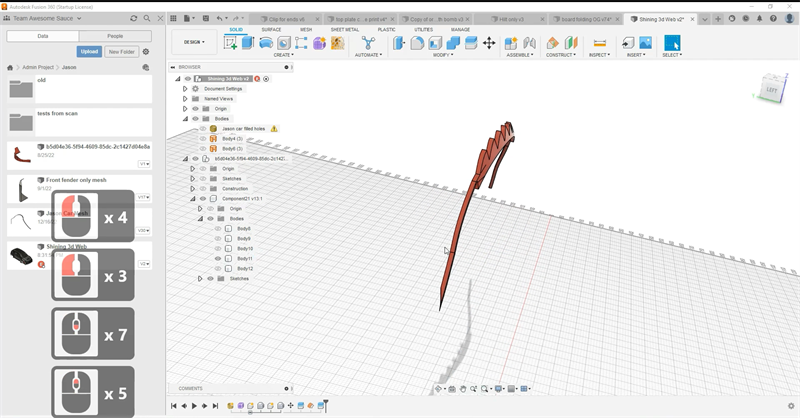

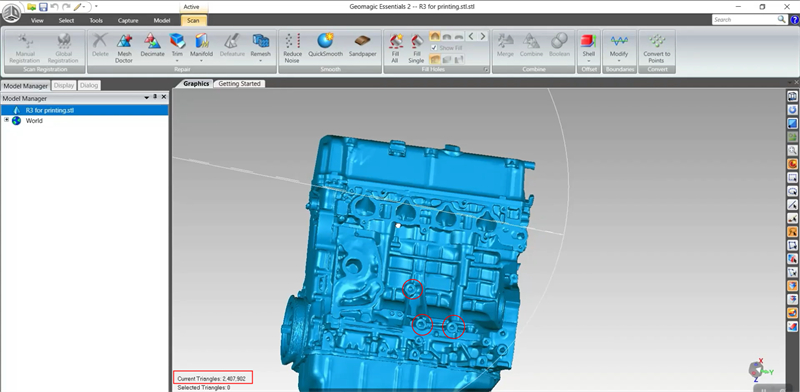

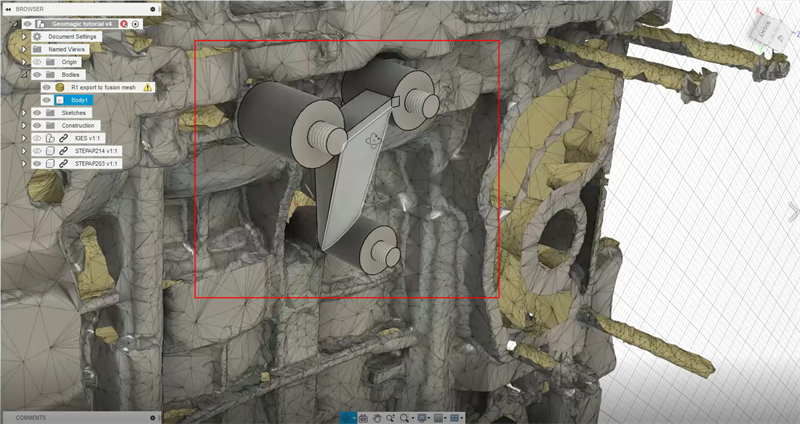

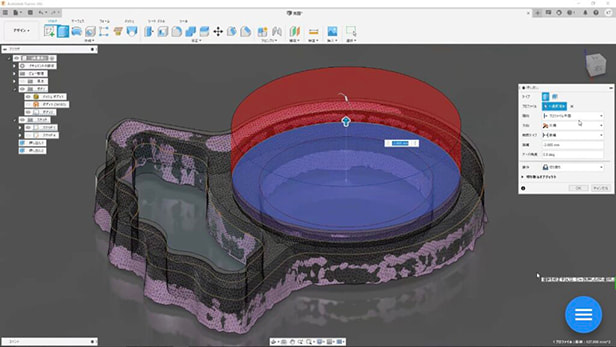

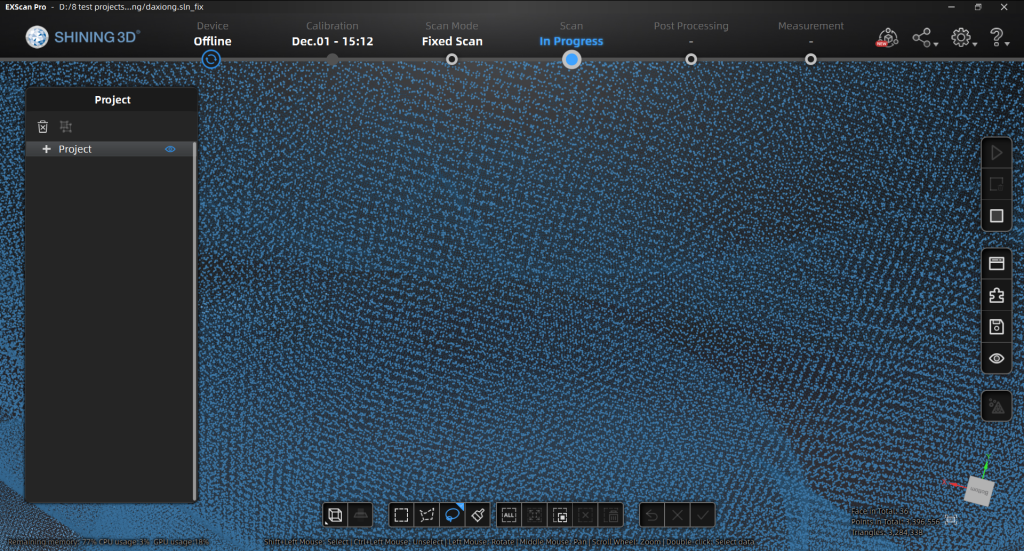

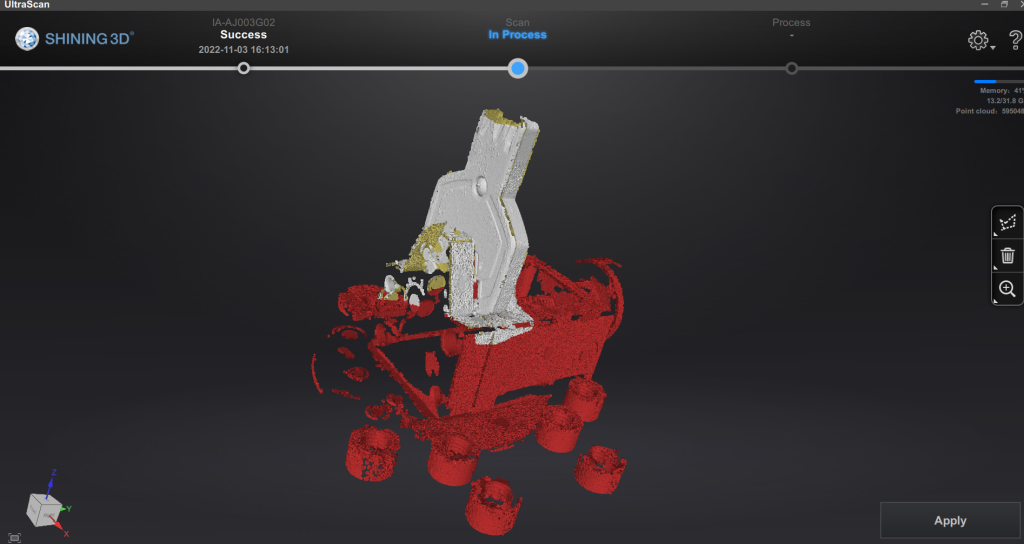

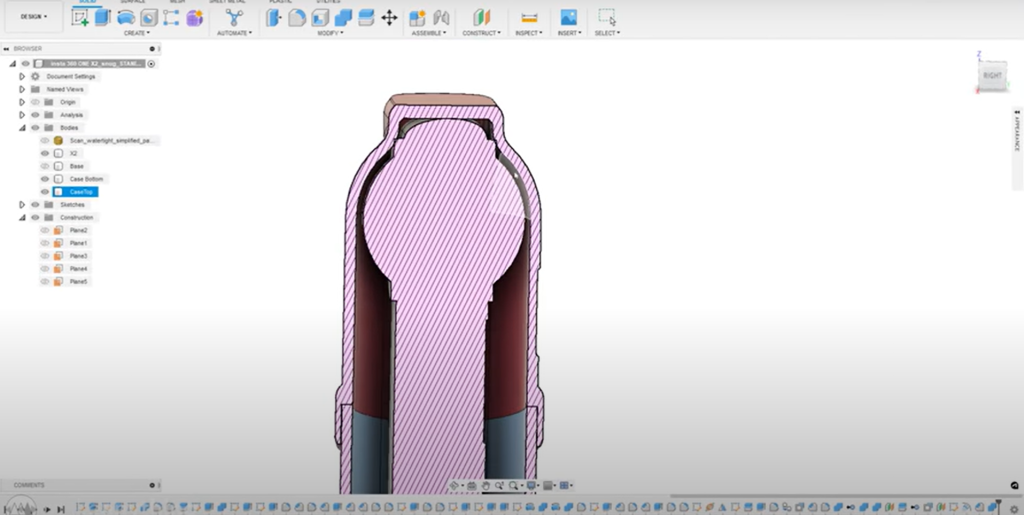

Edward Van Zyl, a seasoned 3D scanning and printing expert from Manitoba, heads the company Dreamworks 3D Printing and Scanning. With extensive expertise in vintage car restoration and customization, he is enthusiastic about utilizing state-of-the-art equipment to capture intricate details of automotive components and then utilizing software to generate accurate 3D models. This article, courtesy of Shining 3D, deep dives into the tips utilized by Edward for scanning with the EinScan HX Hybrid Light Source Handheld 3D Scanner and the reverse engineering of car parts through the use of Geomagic Essentials and Fusion 360. Scanning And Printing An Arrow 50 Scooter Part Edward embarked on a projet to 3D scan and reverse engineer an Arrow 50 scooter part and then 3D print. He chose the EinScan HX Hybrid Light Source Handheld 3D Scanner for this reverse engineering project. In the 3D scanning process, Edward provides a small tip: utilizing miniature pyramids as markers rather than some of the markers that need to be put directly onto the object. This has the advantage of saving time and cost, as it eliminates the need for post-scan cleaning and the small pyramids can be reused. You may download files of pyramids here. In laser scan mode, EinScan HX has a maximum scan speed of 480,000points/s. It just took around 12 minutes to complete the whole scan of the component. And the laser scan mode of EinScan HX makes the scanned data accurate up to 0.04mm, thus you get a very accurate model for subsequent work. Below is the 3D printed part from Bambu Lab X1-Carbon Combo 3D Printer. Cutting A Fender Using Geomagic Essentials Edward’s goal was to cut a fender and make sure it was the right size for installation. Usually, he will print out the part for test, and in this case he offers an easy-to-print and material-saving trick. He creates a small offset about 5 mm or even less, and cuts the part again, so that he gets a tiny piece of the fender, but maintains the geometry he need. 3D printing this thin piece was just as good for installation testing, and using only a minimal amount of printed material. Reverse Engineering An Engine Using Geomagic Essentials And Fusion 360 Furthermore, Edward uses Geomagic Essentials to extract features on the engine, and then using Fusion 360 to model the three holes in which he wants to simulate the mounting bolts. One thing to keep in mind here is that you need to maintain the mesh and the extracted features in uniform coordinates. This step ensures that the extracted features can be overlayed on the mesh in the right position. After extruding two cylinders of different sizes and modeling some threads, the mounting bolt is done. This is basically how to go from scanning to printing of a part; how to use a mesh and model mounting bolts in Geomagic Essentials and Fusion 360. And it is clear how much can be done with a bundle of 3D scanners and softwares. You may find more operation details in the playback video. If you found this content useful, please follow Shining 3D's webinar pages, so you won’t miss out on more information. Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

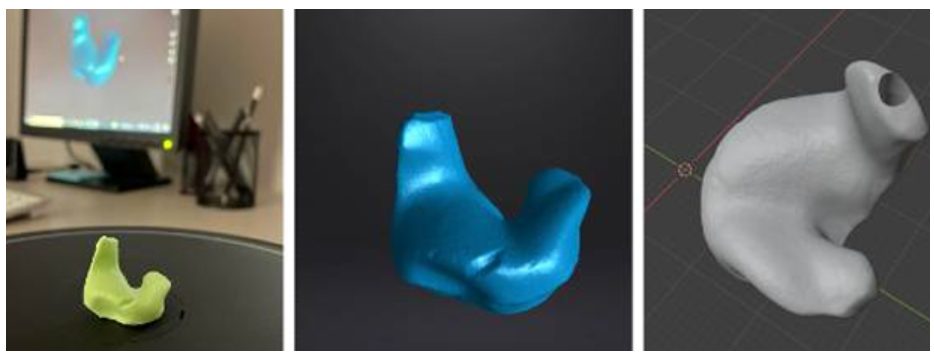

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D Are you still using calipers? Have you tried reverse engineering using 3D scanners? It's a new tool for an old task. Merriam-Webster defines reverse engineering as "the process of disassembling and examining a product or device to discover the concepts involved in its manufacture, usually with the goal of producing something similar." As the design process is beoming digitized, reverse engineering today is more commonly associated with the process of converting a physical object’s geometry into a digital 3D model and replicating the original design or further improving for new manufacturing processes such as additive manufacturing. More engineers are moving away from using calipers and adopting 3D scanners to take measurements, especially of complex parts. 3D scanners allows you to digitally capture the geometry of even the most complex parts in an extraordinarily quick and precise manner. A large docking pump was recently captured in just 20 minutes for example, with the help of laser 3D scanning. This technology has enabled the use of reverse engineering in situations beyond simple benchmarking and part reproduction, as we explore in the next section. Main Applications for 3D Scanning & Reverse Engineering Reverse engineering with 3D scanning offers many possibilities for product development and manufacturing. Overall, the different uses of reverse engineering can be divided into three major applications: (1) to replicate parts, (2) to create variations of existing parts, or (3) to develop entirely new parts based on an existing environment or object. Let's look at each application in a bit more detail. 1. Recreate & Replicate Parts One of the most popular uses for 3D scanners is recreating damaged or worn-out parts that are unavailable from the original supplier or lack proper documentation. This is a common problem when working with old machinery or vintage vehicles, and it’s always challenging to do with manual reverse engineering tools like calipers. However, with a good 3D scanner and the proper software, it can become a straightforward task. Katsuya Tanabiki, for example, shared his process of reverse engineering a shield notch on an old motorcycle helmet. The helmet featured two shield notches, but one was broken, and it was too difficult to obtain a replacement notch. This tiny part was 3D scanned with an EinScan Pro 2X in Fixed Mode, and later 3D printed.

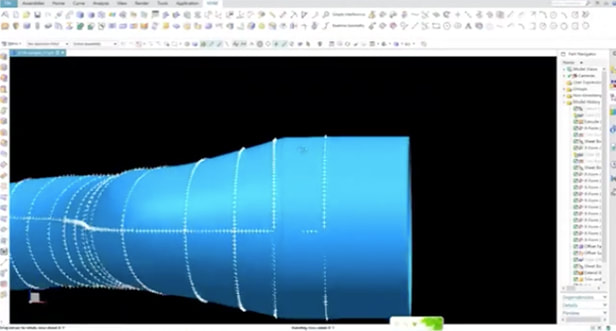

2. Improve The Design of Existing Parts Another goal of reverse engineering is to use digitized parts to create new and improved variants instead of merely reproducing them. This method can significantly reduce the time and costs of creating parts from scratch and also ensures a perfect fit for components belonging to larger assemblies. Taiwanese company Kiden Design has illustrated the reverse engineering process of optimizing a pipe using 3D scanning, CAD, and 3D printing. The EinScan Pro HD 3D scanner, used in Handheld mode, captured the irregular geometry of the pipe on two opposite sides that were stitched together later in software. Thanks to the accurate 3D model obtained, the geometry could be easily optimized in CAD.

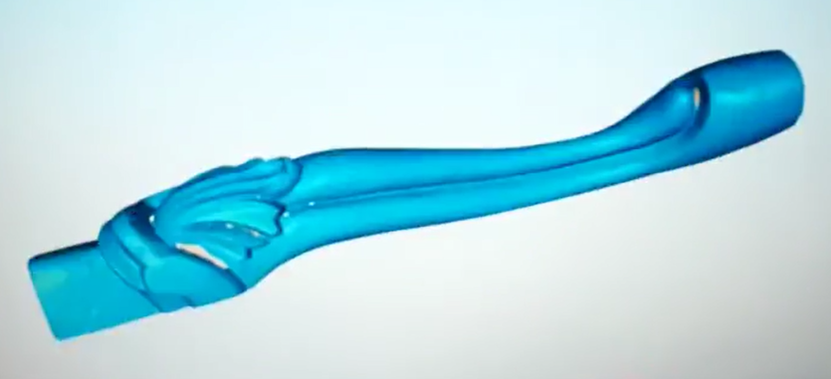

3. Create & Design Entirely New Parts Another application for reverse engineering is where a part is digitized as a reference to create entirely new parts. This procedure is usually employed when a tight fit is required on an existing part that is too complex or has an irregular interface.

This particular technique is also commonly practiced by medical professionals since body parts are unique and challenging to accurately replicate using manual methods. Here, 3D scanning once again has proven to be an efficient tool for digitizing human parts and surfaces. Earmolds, for example, are patient-specific parts that help conduct sound from the hearing aids to the ear canal. Servicing or creating new earmolds from scratch can take several weeks during which patients experience hearing problems without them. However, thanks to reverse engineering methods with 3D scanning and 3D printing, the Hearing Beyond Audiology Clinic in Toronto can produce temporary earmolds in just one day. The temporary accessory allows patients to keep their hearing while waiting for the earmolds to be produced or serviced in other facilities. Similar reverse engineering methods with 3D scanning are also utilized for producing facial prosthetics and custom orthotics. Quality Data Capture Is Key for Successful Reverse Engineeing The use cases above clearly demonstrate the central role of 3D scanning in reverse engineering. It comes as no surprise that the effectiveness and accuracy of data captured by 3D scanning are crucial for a successful reverse engineering process. Yet, the software tools used for processing the data and working with the 3D models are also essential for achieving the desired results in reverse engineering. To understand the importance of good data and adequate software, let’s go over the main steps of reverse engineering with 3D scanning. Step 1. Data acquisition The very first step in any reverse engineering process is data acquisition. Regardless of the method, proper planning and preparation can make the difference between good and poor data. With 3D scanning, this involves selecting the correct device for the job, including the proper configuration (handheld or stationary) and accessories such as turntables, fixtures, and calibration panels. Correct calibration of the device is also vital to acquire quality data. The regions or parts to be digitized usually demand some kind of preparation. Besides a good cleaning, some 3D scanning devices also require the use of markers or even special coatings on reflective surfaces. One should also consider the ambient conditions before starting the digitization process. A controlled environment (e.g. indoors, without direct sunlight, a cleared tabletop, …) is always preferred to reduce noise in the data, but that’s not always possible. All the factors mentioned will contribute to proper data collection, which will in turn determine how quickly and easily the data can be processed next. Step 2. Post-Processing The next step in a reverse engineering process is post-processing the acquired data, or the “point cloud”. Here, the point cloud is processed by software tools – like EinScan software – resulting in a 3D mesh representation of the digitized object. In any case, the 3D model in this initial stage usually requires some refinement like removing unwanted captured data, repairing surfaces, and filling gaps per below. The better the data quality acquired, the less post-processing and repairing will be needed. The post-processing step is also when reference entities are assigned to the 3D model, a procedure that should expedite the next stage of the reverse engineering process. Step 3. CAD Model Generation The final step in a reverse engineering process is to convert the mesh representation of the physical object captured by the 3D scanner into a solid 3D model. As accurate as the mesh model can be, it is inadequate for most reverse engineering applications that require additional handling like fixing any physical damage, creating variations, or designing new parts altogether. In this stage, the refined mesh model from the previous step works as an exact reference model for recreating the model using parametric CAD tools. Although in theory any general-purpose CAD program could handle this, specially purposed software geared towards reverse engineering can make the process much easier and yield much better results too. An appropriate CAD software for reverse engineering can also compare the digitized model to the parametric one, allowing users to check for geometrical and dimensional differences. Conclusion Reverse engineering has come a long way and 3D scanning technologies have broadened the range of industrial applications for reverse engineering, benefiting both businesses and consumers. The quality of the captured data is crucial to obtain good results in reverse engineering. The choice of the 3D scanning device, as well as its capabilities and functions, play a central role in the success of the entire process. Read further about how to make sure you choose the right model for your project here. Though often overlooked or underestimated, the software used in the later stages of reverse engineering also bears great importance. Specific built-in tools for the job can make a big difference in a well-executed reverse engineering process. Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D |

GrowshapesProvider of leading edge 3D scanning products and services. We see 3D! Archives

July 2024

Categories

All

|

|

Vertical Divider

GROWSHAPESStay connected |

Menu |

©2024 Growshapes LLC. All rights reserved.

RSS Feed

RSS Feed