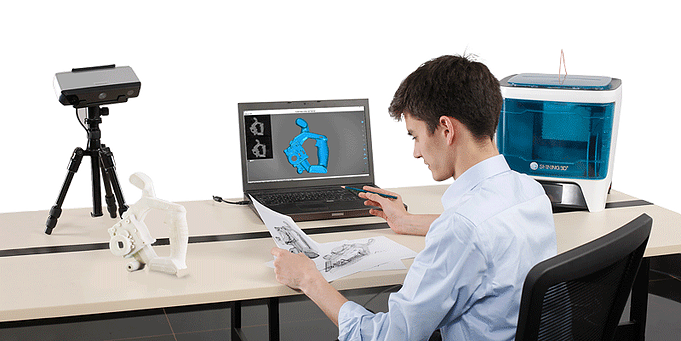

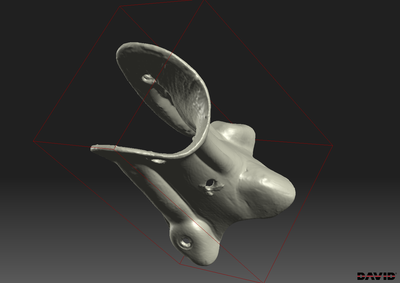

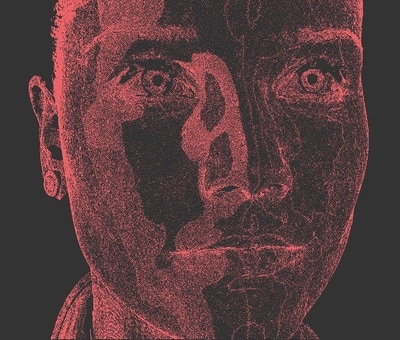

Want to create a digital replica of your artwork in 3D?

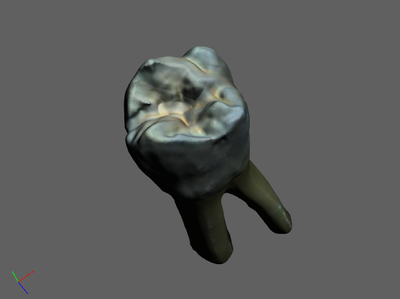

Want to measure the absolute scale of an organic form?

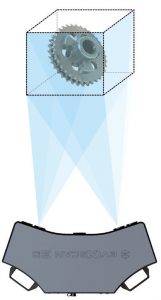

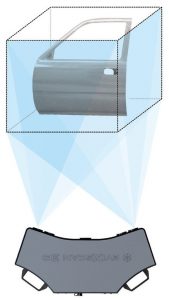

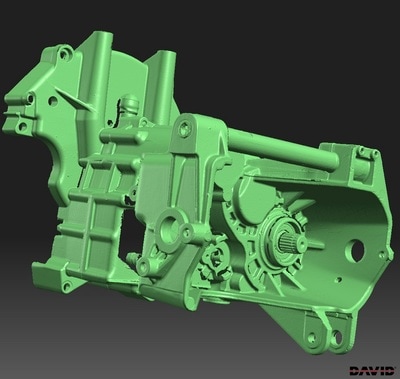

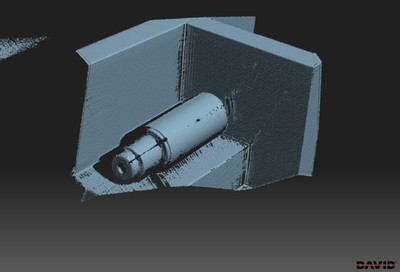

Can't find the blue print of the parts you need?

Want to measure the absolute scale of an organic form?

Can't find the blue print of the parts you need?