LET'S TALK ABOUT 3D SCANNING |

|

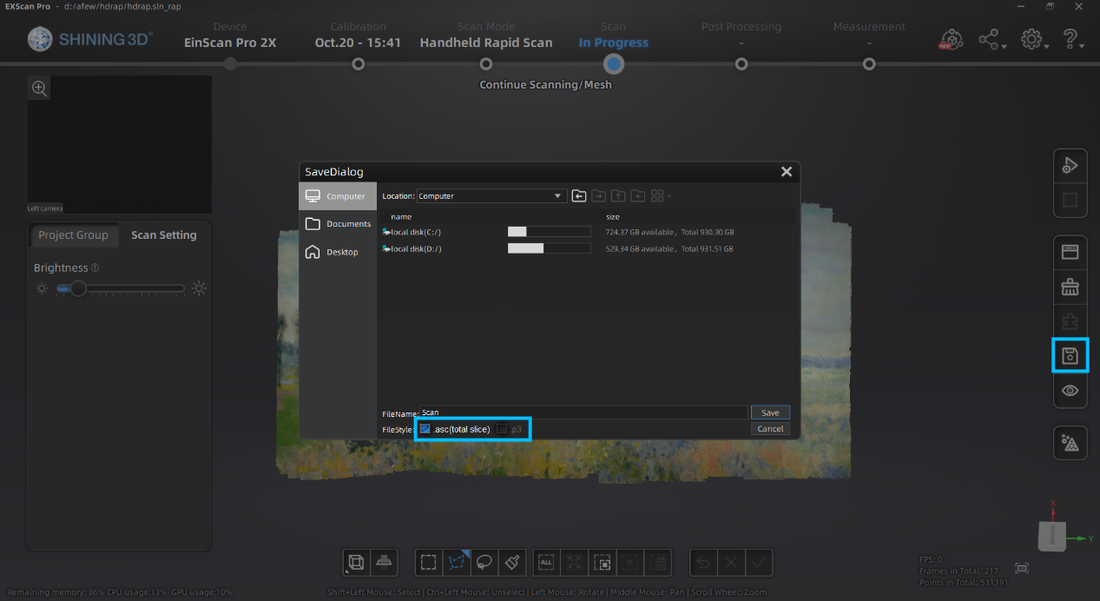

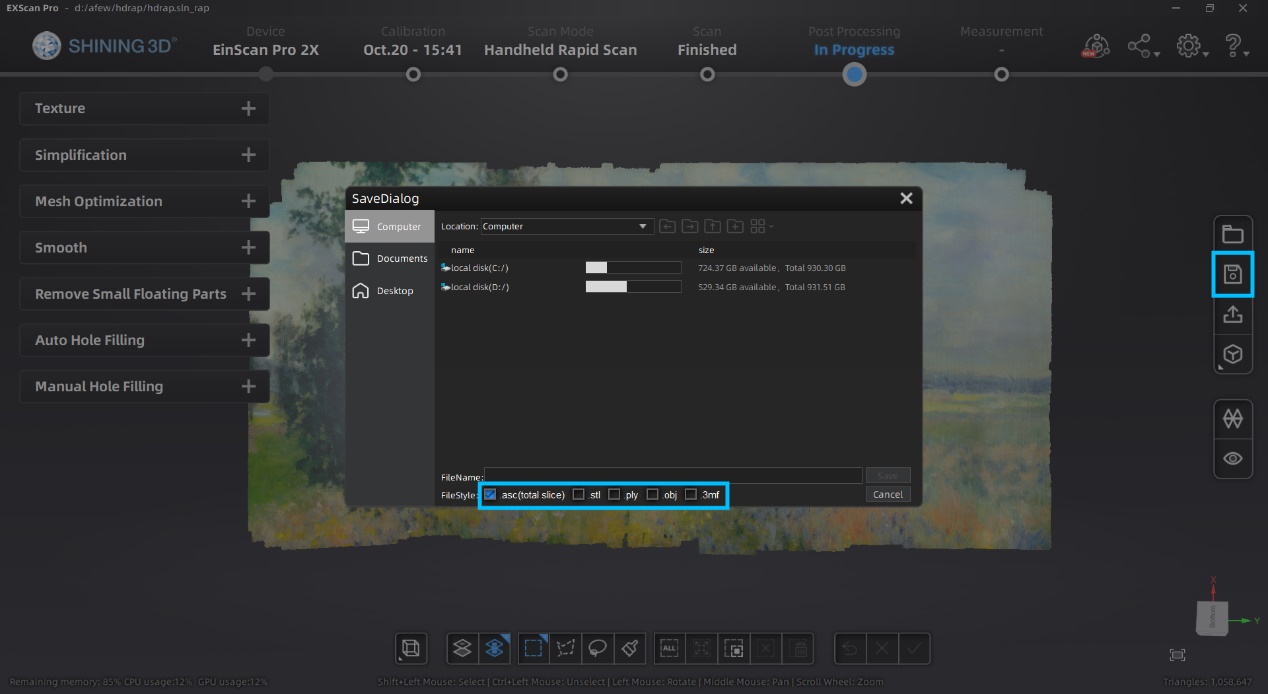

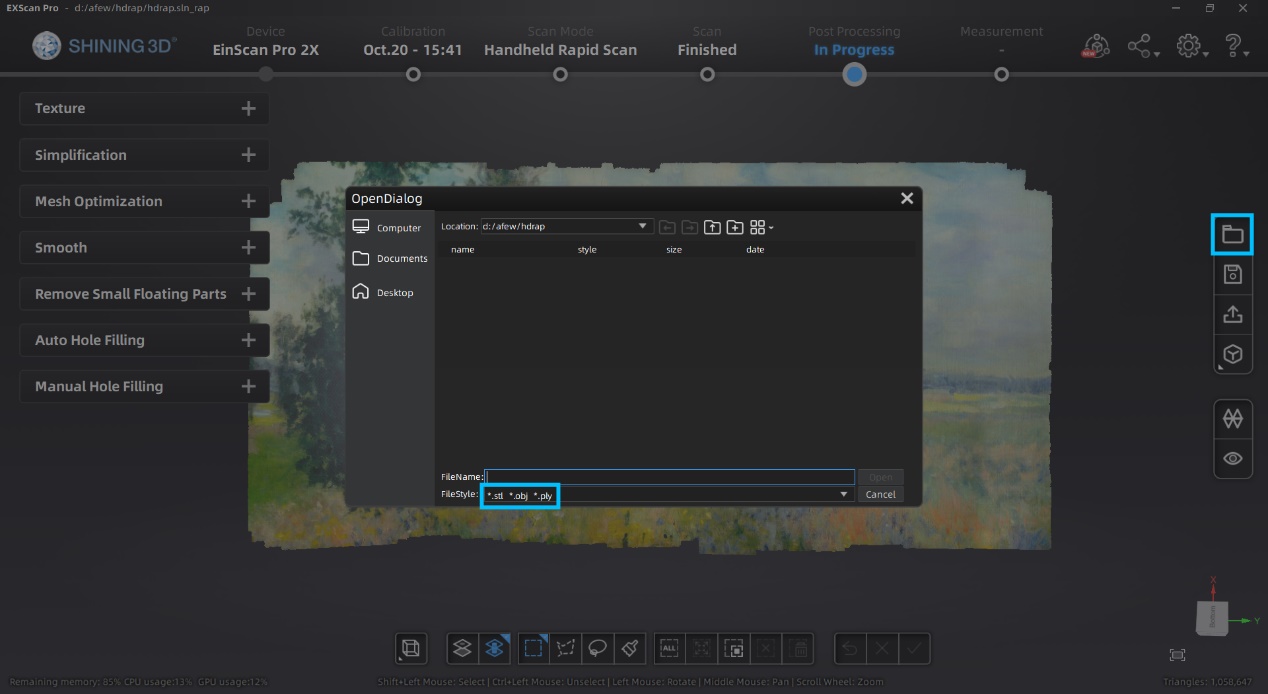

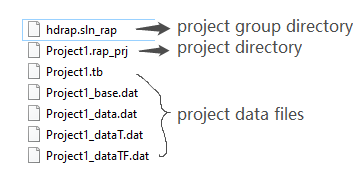

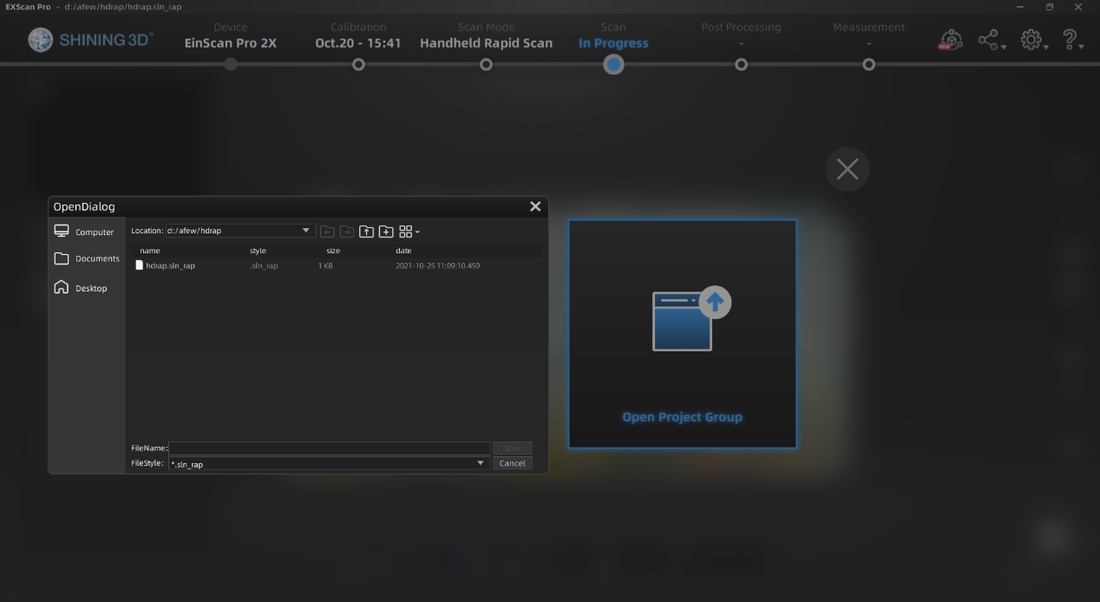

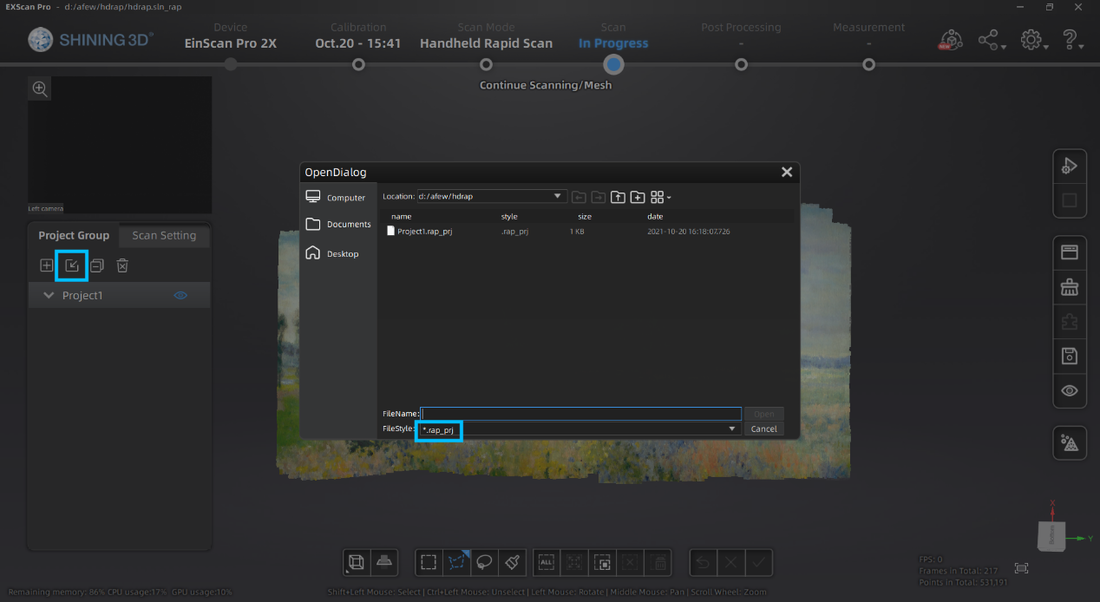

3D scanner is a data-acquiring device that captures the surface model of a physical object in a digital polygonal model. The types of output data format that 3D scanners can generate maybe confusing. What is an ASC file? Which export formats does my CAD software import for rapid prototyping? What is the best practice for saving scans? Which file format is the best choice for 3D printing? In this post, we will discuss all file types that involve Einscan software. The type of file you require depends on what you are going to do after the scanning process. There are a total of 6 types of output data formats (ASC, p3, STL, PLY, OBJ, 3MF) that you can export from EinScan software during data capture and generating mesh which are polygon models. We will explain the differences among these 6 file types in this blog. Point Cloud Data Format When you have finished your scan and are ready to convert your raw scan data to point cloud data, you can click on the save button to save the point cloud data as an ASC file and the marker position as p3 format when markers are detected. ASC file contains the position information of each point in the point cloud. This file type can be opened in most scan data processing software and metrology software like Meshmixer, GOM Inspect, and Geomagic Essentials. The P3 file is for marker reuse purposes in EinScan software. For a large object scan, the user can scan all markers only first and save the marker frame as a p3 file. Later the object can be scanned part by part in a separate project using the same p3 file as a reference which improves the accuracy and will require no alignment between each project. With Fix scan mode number of scans will be saved as separate files, while for handheld scans the full point cloud will be saved as one file. Meshed Data File Format After the data is meshed, more saving options will be available. ASC file is still available while the mesh can be saved as STL, PLY, OBJ, or 3MF files. STL file format is the most common mesh file format. It only contains the position and normal directions of all triangles in the mesh. This polygon file format can be opened by mesh editing software and many CAD software like Solid Edge or Solidworks for reverse engineering. PLY and OBJ file formats contain mesh texture information, including color information, in addition to the STL file. Users can export these data types for digital documentation and online model display. 3MF file is the 3D printing format published by the 3MF Consortium. This format includes information about materials, colors, and other information that cannot be represented in the STL format. Windows system and other CAD software packages can open this mesh format. Post Processing Data EinScan software provides basic functions for mesh editing in Post Processing and Measurement sections. Usually, users use these functions right after meshing data. However, external mesh data can also be imported into the EinScan software for editing. The EinScan software supports STL, OBJ, and PLY formats for post-processing and measurement. The project group folder contains different kinds of files. The project group directory links all projects in the group. The project directory links all data files belonging to this project and the rest are project data files. When moving the project group, the user needs to move all the folders in the project group. When opening the project, the user needs to locate the folder where the project group was saved and open the corresponding directory files.The project group folder contains different file formats. The project group directory links all projects in the group. The project directory links all data files belonging to this project and the rest are project data files. When moving the project group, the user needs to move all the folders in the project group. When opening the project, the user must locate the folder where the project group was saved and open the corresponding directory files. So that's it! You have 6 output formats to choose from and all the required scans for your saved project will be in a project group folder. Remember, the file size for each project is large, so make sure you secure a space on your PC where you can save the files. Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

0 Comments

We just wanted to say "thank you" for being our customer and buying 3D scanners from Growshapes! We continue to add select 3D scanners based on structured light technology this year. We have now updated our website with the addition of Shining 3D EinScan 3D scanners including the latest and greatest EinScan Pro 2X and EinScan Pro 2X Plus (bigger scan range vs. 2X) . These 2 new models were announced at Formnext 2018 in Germany this month. Prices start from $5,499. Key to note on EinScan Pro 2X Series:

So if you were thinking of getting a versatile handheld 3D scanner, check out the new EinScan 3D scanners! Growshapes is an HP Silver Partner of HP 3D scanning solutions and the official U.S. distributor of Open Technologies 3D Scanners - an endorsement that makes us proud. We are adding the Shining 3D EinScan 3D scanners to our line up too.

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

Growshapes is proud to announce Mcor celebrated its victory of receiving the Green Award at the 3D Printshow 2014 global awards ceremony in London. Recognized for its unique eco-friendly approach to 3D printing, Mcor is repeatedly noted as being one of the most innovative 3D printers to exist.

The company was awarded for producing a stunning full color paper Durga idol that is impressive not only in detail but also for its wide array of color. Idols can now be designed in India and printed world wide from any Mcor printer which will allow people to stay further connected to their traditions. Read more about the Durga and Mcor's victory. Did you know Growshapes is an official Mcor reseller? Learn more about Mcor 3D Paper Printers directly on our website. |

GrowshapesProvider of leading edge 3D scanning products and services. We see 3D! Archives

July 2024

Categories

All

|

|

Vertical Divider

GROWSHAPESStay connected |

Menu |

©2024 Growshapes LLC. All rights reserved.

RSS Feed

RSS Feed