LET'S TALK ABOUT 3D SCANNING |

|

Recently the media picked up a story about how 3D printing saved the day to produce valves for an intensive care unit in Italy to treat COVID-19 patients. The Italian startup company reverse engineered, and 3D printed these valves that are key components of Venturi oxygen masks that are connected to ventilators. When you read the details however, you realize they jumped various legal hurdles to do this - the valve is protected by copyright and patents with its blueprint not released but in an emergency case such as this one, the hospital seemed to have allowed them to reverse engineer the valve and 3D print them. The CEO of the company that 3D printed the valves is now is explaining what his intentions were on his Facebook post and LinkedIn video (in Italian). When emergencies of such enormous scale occur as is happening right in front of our eyes, you just want to help if you have the capability and technology to solve the problem quickly. But regulations exist to ensure safety and durability thus everybody in the 3D printing industry is doing a thoughtful balancing act. It is not clear if they used a 3D scanner or just used calipers to do the reverse engineering but 3D scanners can play a key role in enabling accurate and quick reverse engineering of physical objects. Using 3D scanning technology, you can capture the surface dimensions of complex physical objects accurately and quickly especially with the structured light 3D scanners, then then reverse engineer with various CAD software such as Geomagic and Solid Edge which comes bundled with EinScan Pro 2X & 2X Plus to create a blueprint that can be 3D printed. Have a look at how you can reverse engineer products that are missing a blueprint by using 3D scanners. https://www.growshapes.com/einscan-pro-2x-3d-scanner-series-bundle.html Growshapes is an HP Silver Partner of HP 3D scanning solutions and the official U.S. distributor of Shining 3D EinScan 3D scanners. We are now carrying the eviXscan 3D scanner from Evatronix too!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D.

0 Comments

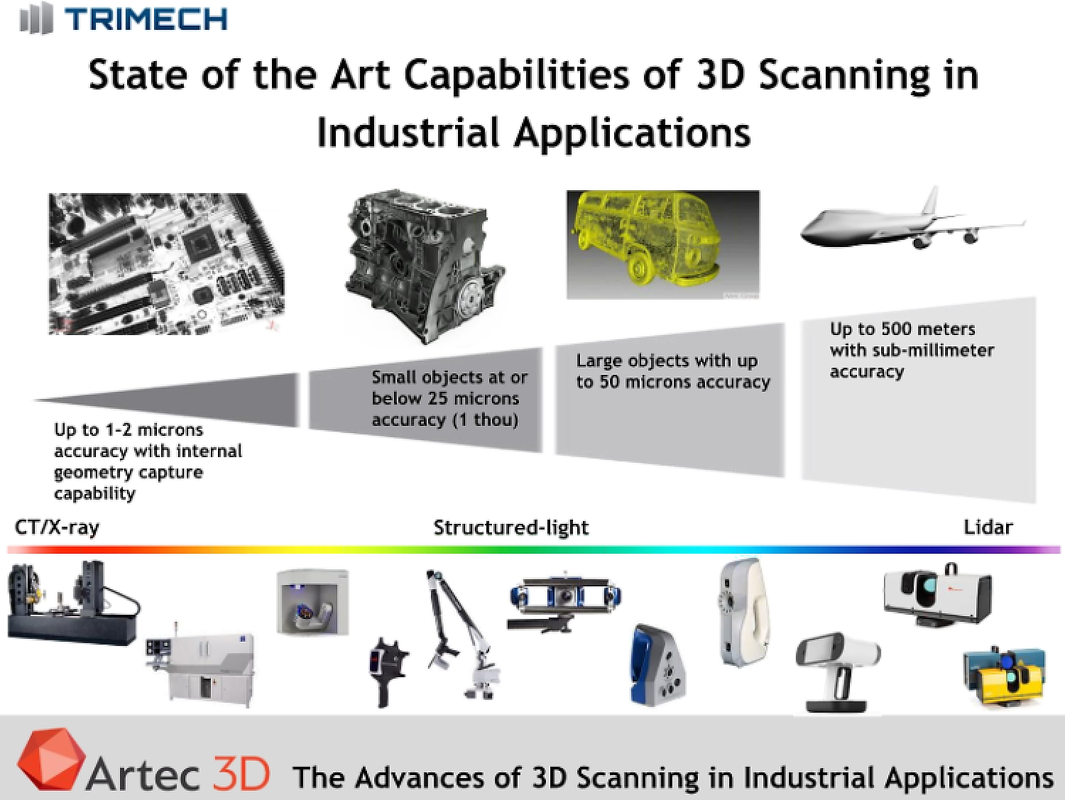

Have you ever wondered which technology within 3D scanning would be most suitable for your reverse engineering, measurement or inspection needs? Trimech hosted a great webinar where Artec explained per below, how different 3D scanning technologies cover different spectrums of industrial applications. Growshapes carries HP's and Open Technologies' structured light 3D scanners which are stationary, not handheld like the Artec 3D scanners. While the handheld scanners enables to move around especially large objects more easily, the stationary models like HP Pro S3 or Open Technologies Cronos uses an automatic turntable whereby small to medium size objects are placed onto the turntable which rotates at set angles, making the alignment more accurate and easy, achieving 50 micron level accuracy even with the mid-end HP 3D scanners. The Open Technologies Cronos can achieve 15-30 micron level accuracy. Different applications require different 3D scanners as you can see above. You may need a stationary one vs. handheld or vice versa. If you are not sure which is the best 3D scanner to buy for your needs, just call us or email us so we can help you. Even if Growshapes do not carry the exact product you want, we have a great network in the industry and we are more than happy to help you connect with the right people to get the 3D scanner you need! Growshapes is an HP Silver Partner of HP 3D scanning solutions and the official U.S. distributor of Open Technologies 3D Scanners - an endorsement that makes us proud.

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

Description Learn about the latest developments with netfabb software for 3D printing, including how it uses structures to create brand new materials which do not exist in nature (biomimicry), and more with Ulf Lindhe, Business Development Manager at netfabb GmbH. It has been a year since Ulf's last presentation to our group. This is a great opportunity to find out what's new. Some netfabb testimonials (http://www.netfabb.com/testimonial.php): - "netfabb is a very significant development in software for design of parts for manufacturing using rapid prototyping technologies. The software frees the product development engineer from the limitations of complexity and file size in conventional CAD programs. We use the software for designing lightweight high performance ceramic structures with tailored macro and micro porosity." Andrew Jeffery, Founder and President, Viridis Innovation LLC, Boston MA, www.viridisinnovation.com - "netfabb’s Selective Space Structures (3S) has been incredibility useful to us. It is the only software we have found to date that is capable handling and producing large net structures required for the scale of components we produce for the aerospace industry." - “We were pleased to find netfabb a reliable and powerful software capable of producing complex lattice structures with locally tailored geometry. In the design of customized Titanium Implants, such a capability proves to be very useful in enhancing bone response and controlling the mechanical behavior of the implants. The software has very intuitive commands that enhances the creative design of structures, minimizing time and memory usage, making the production of parts with very high complexity a breeze rather more than just a possibility.” Gilbert Chahine, Research Assistant and PhD Candidate, Research Center for Advanced Manufacturing, Lyle School of Engineering, Southern Methodist University, Dallas, Texas, USA http://www.smu.edu/Lyle/Departments/ME/Research/RCAM.aspx Contact growdhapes ([email protected]) for special invitation

Highlights of netfabb 3D software's recently released upgrade to version 5.2 include:

For more information on each of these exciting new features related to 3D printing, click here. netfabb Professional 5 users get the upgrade for free! Simply click on the "Help" menu and select "Upgrade netfabb." netfabb Studio Professional 4.X users can upgrade to version 5.2. Contact GrowShapes for more information. DAVID Vision recently released an update to their 3D scanner software. The full version number is: 3.10.4.4657

DAVID_Setup_3.10.4.4657.exe (6.71 MB) This is an installer for the latest version of DAVID scanner Free Edition, 32 and 64-bit, including the trial edition of DAVID-Shapefusion. The calibration patterns are included as PDF and CDR files. Languages: English, Chinese, Czech, Estonian, French, German, Greek, Italian, Polish, Russian, Spanish, Turkish Prerequisites for execution:

The download file on the DAVID website is located here. Installation:

The DAVID scanner creates 3D data for reverse engineering, quality inspection,product development/prototyping, art art and science, medical use and more. growshapes and the soon-to-launch Silicon Valley 3D Printing Accelerator will be hosting an Open House this evening from 6:30 to 8:30pm at their Santa Clara office for the Silicon Valley chapter of the Industrial Designers Society of America (IDSA-SV).

As part of the Open House, growshapes CEO, Geoffrey Doyle will give a brief presentation on biomimicry and industrial design. His talk will focus on how the development of new structures (or combining existing structures in new ways) enables the development of new 3D printing materials. Geoffrey will also illustrate how new structures and 3D printing technologies will dramatically impact the way prototypes and products are manufactured. There will also be product demonstrations:

Registration information can be found here. |

GrowshapesProvider of leading edge 3D scanning products and services. We see 3D! Archives

July 2024

Categories

All

|

|

Vertical Divider

GROWSHAPESStay connected |

Menu |

©2024 Growshapes LLC. All rights reserved.

RSS Feed

RSS Feed