LET'S TALK ABOUT 3D SCANNING |

|

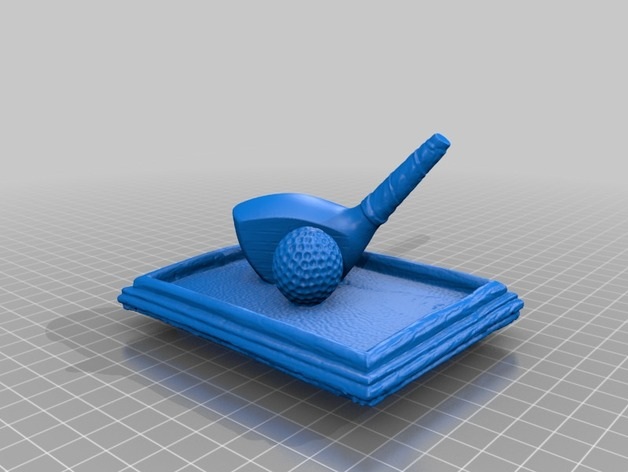

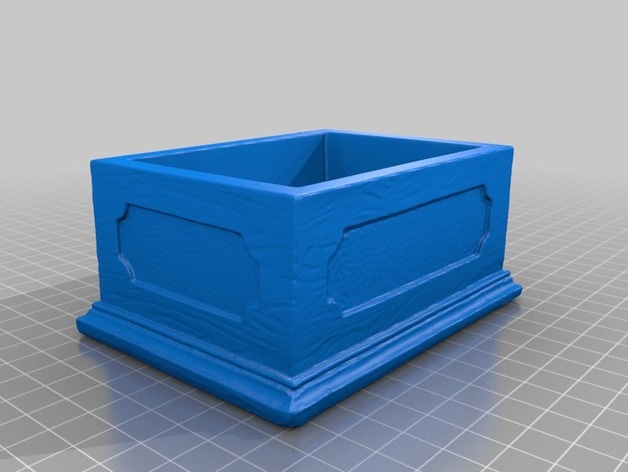

Check out what one of our customers billyd have scanned and posted on Thingiverse! The automated turntable does make the 3D scanning very accurate. You can 3D print this nice box by downloading his high quality 3D scan files.

0 Comments

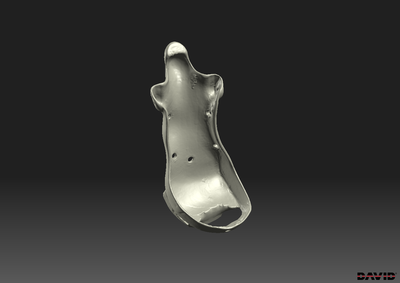

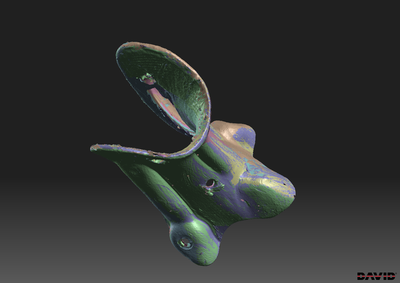

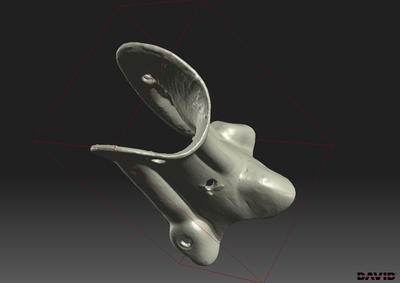

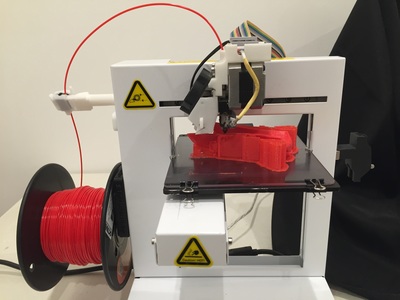

When Jane told us about her disabled dog Tbone who wears supportive shoes to enable him to walk and how much it costs to have them custom made, we thought why not 3D scan, 3D print and see if it works..... So here is the story of how we scanned, printed then bound the parts together to recreate Tbones' shoes using the latest 3D scanning and printing technology! STEP 1: Set up of the DAVID SLS-3 3D Scanner This is a quick video of the setup of equipment used: DAVID SLS-3 3D Scanner, Desk Scan Lever (DSL), Automated Turntable (TT-1), Calibration Panel, UP! Mini 3D Printer. Step 2: Scanning and printingThe process from 3D scanning to 3D printing: Tbone's old dog shoes were scanned which comprised of 2 parts for each leg, the upper part and the bottom part. Since the original shoes were made in black, we painted them white to be able to scan them as black absorbs light. You can also coat objects with white powder that washes off if you need the original object in its original color when finished. This is how you overcome scanning shiny or dark objects. When we finished scanning, we sent the 3D scan files to the UP! Mini 3D printer to print in red and blue ABS plastic. For our 3D printing needs we always turn to Octave - thanks guys. STEP 3: Putting the shoes togetherThen Jane glued them, put the straps on and bound them together STep 4: Putting it on tbone!Finished product fitted on Tbone! This was a test so we are further thinking about different materials to use for better flexing, slight size adjustment (Tbone's old shoes we scanned were a bit worn) etc, but so far so good!

Awesome video! You can learn all about the different 3D scanning technologies - laser, infra red and structured light. Structured light is the technology DAVID VISION 3D scanners uses which has a very big advantage in speed and the DAVID software provides accuracy. This video mentions the downside of structured light that it cannot scan shiny or dark objects, but actually if you spray white powder like Magnaflux Spotcheck or even Athlete's foot spray like this one onto the object, you can scan any object perfectly! Once you're done with the scanning, you can just easily wash the white powder off. |

GrowshapesProvider of leading edge 3D scanning products and services. We see 3D! Archives

July 2024

Categories

All

|

|

Vertical Divider

GROWSHAPESStay connected |

Menu |

©2024 Growshapes LLC. All rights reserved.

RSS Feed

RSS Feed