EinScan 3D Scanner Case Studies

|

Vertical Divider

Medical3D scanning body parts to create custom orthotics.

|

Vertical Divider

Reverse Engineering3D scanning automotive parts for reverse engineering and design development.

|

Design3D scanned elements of nature that was then applied into to jewlery design. Read the full story here.

|

eviXscan Case Studies

|

Vertical Divider

Design DevelopmentOne of the challenges in this project was to digitize the compound curved components that were hand sculped into CAD models so that moulds can be manufactured for production lay-up of the carbon fiber parts.

Read the full story here. Shapers uses eviXscan HD Quadro

|

Vertical Divider

Quality ControlThe use of eviXscan 3D scanner in the quality control department allowed for precise control of the quality of finished products by comparing them to original CAD models supplied by customers. Read the full story here.

Automated Quality Control

|

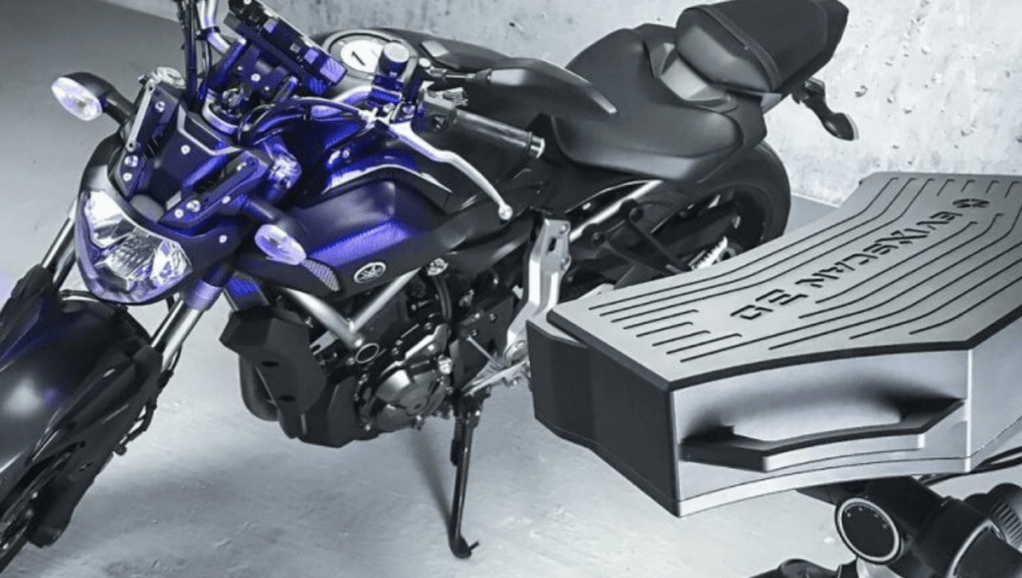

Reverse EngineeringLoster is the only company in Poland that uses the eviXscan 3D scanner to reconstruct fairings that are no longer available on the market. Read the full story here.

Reverse Engineering |

HP 3D Scanner Case Studies

|

Vertical Divider

Digital Animation at Middlebury College:

3D scanning of hand-made clay models with the HP 3D Structured Light Scanner Pro S3 enables animators to create digital animation characters with a human touch. “With the arrival of the HP 3D Structured Light Scanner, finally we were able to begin with art first and wrestle with technology second.”

- Daniel Houghton, Director, Middlebury College Animation Studio

Your browser does not support viewing this document. Click here to download the document.

|

Archaeological and Historical Services at

Eastern Washington University: Using the HP 3D Scanner Pro S3, archaeologists have been able to verify their hypothesis and unlock some of the mysteries of the past much more easily than before. “If more archaeologists adopted 3D scanning then we would be able to greatly increase the dataset. And that would allow us to interact better with the public and even each other.”

- Julia Furlong, Archaeologist, Archaeological and Historical Services, Eastern Washington University

Your browser does not support viewing this document. Click here to download the document.

|

Application of 3D Scanners in Different Industries

Learn how HP 3D Structured Light Scanner (formerly known as DAVID SLS 3D scanners) have been used in different industries and see what the users are saying.

|

Medical Device Development

Rusty Hitch of Beckman Coulter needed precise 3D scans of existing medical equipment for prototyping research. Kinect-based systems were not up to the task, so Rusty turned to Growshapes.

|

Biomedical

Advanced Biologics was struggling to capture small bio-object data with more expensive 3D scanning systems. Growshapes provided a working solution at 1/3 the cost.

|

Automotive Reverse Engineering

This automotive engineering company was able to successfully measure precise data of the small metal components, which was not possible with an Artec solution which costed this company 6 times as much as that of DAVID SLS 3D scanners.

|

|

Vertical Divider

GROWSHAPESStay connected |

Menu |

©2024 Growshapes LLC. All rights reserved.