- Best Sellers

- >

- EinScan H2

EinScan H2

SKU:

6970163084121

$5,299.00

$5,299.00

Unavailable

per item

The EinScan H2 improves on its predecessor with 5MP resolution texture camera, Enhanced accuracy up to 0.05mm in IR mode and 3 infrared VCSEL projectors

Its wide scanning area and adjustable working distance make it suitable for various scenes and objects, both small and large, in narrow or wide spaces. Optimized for face and body scanning with flashless infrared technology, advanced hair enhancement algorithm that captures both light and dark hair as well as the non-rigid algorithm in IR mode that automatically compensates for slight movements to eliminate misalignment challenges.

EinScan H 3D Scanner | Calibration Panel | Markers | ExScan H 3D scanner software (perpetual license with automatic updates)

Its wide scanning area and adjustable working distance make it suitable for various scenes and objects, both small and large, in narrow or wide spaces. Optimized for face and body scanning with flashless infrared technology, advanced hair enhancement algorithm that captures both light and dark hair as well as the non-rigid algorithm in IR mode that automatically compensates for slight movements to eliminate misalignment challenges.

EinScan H 3D Scanner | Calibration Panel | Markers | ExScan H 3D scanner software (perpetual license with automatic updates)

EinScan H2 Technical Specifications

EinScan H2 in Action

|

Vertical Divider

Overview

|

Vertical Divider

Scanning in IR Mode

|

Scanning in White Light Mode

|

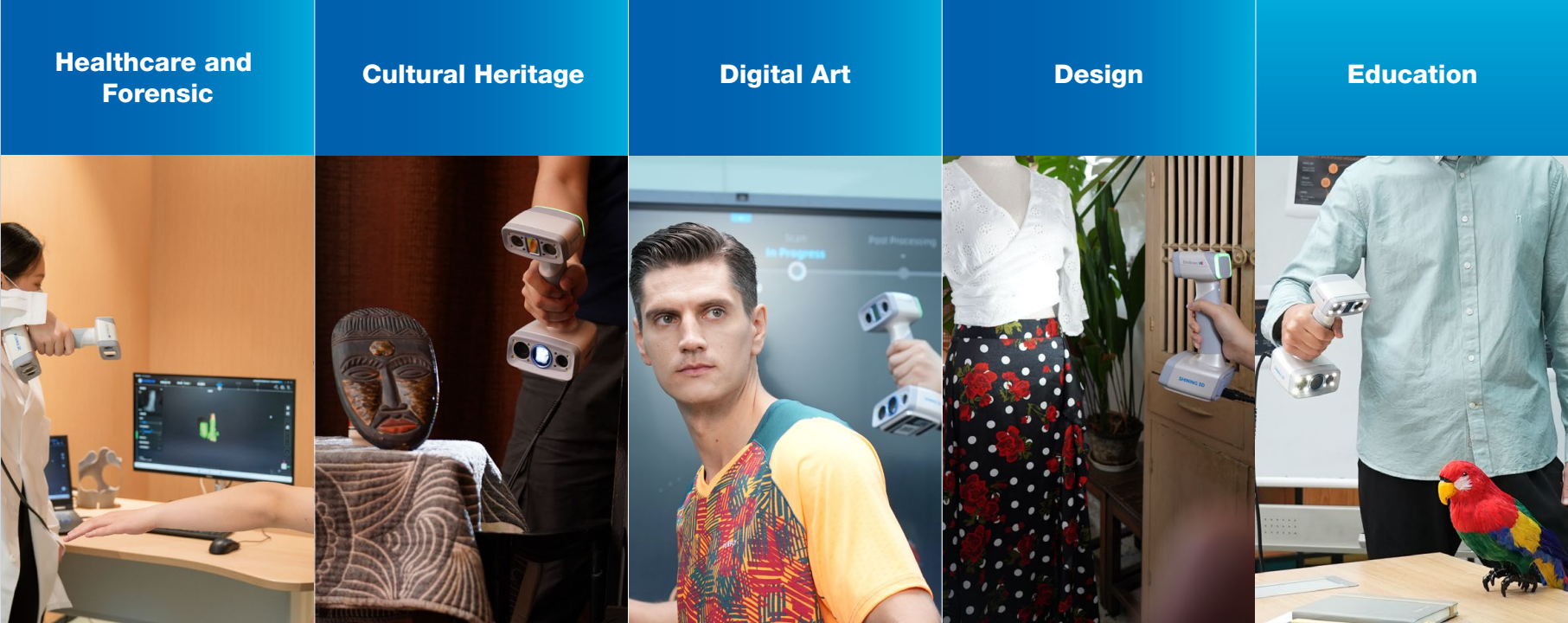

EinScan H2 Applications

EinScan H2 Orthotics and Prosthetics Workflow

Benefits of the Digital Workflow

- Personalization: Creates prosthetics that are highly customized to the individual's physiological and lifestyle needs.

- Efficiency: Reduces production time and allows for rapid prototyping and adjustments.

- Innovation: Enables the design and production of complex, lightweight structures that were not possible with traditional manufacturing methods.

- Patient Involvement: Facilitates a more collaborative approach, allowing patients to have a say in the design and functionality of their prosthetics.

-

Step 1: 3D Scanning

-

Step 2: Design Prosthetics

-

Step 3: 3D Print or Mill

-

Step 4: Fitting

-

Step 5: Monitor & Follow Up

<

>

- Patient Consultation: Begin with a detailed consultation to understand the patient's specific needs, medical history, lifestyle, and expectations from the prosthetic.

- 3D Scanning: Use a 3D scanner EinScan H2 to capture precise measurements (0.02 mm accuracy) and the contour of the limb or body part where the prosthetic will be fitted. This scan generates a digital model that serves as the foundation for designing the custom prosthetic.

- Import Scan Data: Load the 3D scan data into a CAD (Computer-Aided Design) program specialized for prosthetic design. This software allows for intricate manipulation of the model to tailor the prosthetic to the patient’s exact dimensions.

- Customization: Modify the design to ensure optimal fit, function, and aesthetics. This can include adjusting the shape, adding sockets for comfort, customizing the grip for hand prosthetics, or integrating components for mobility and flexibility. The software that we recommend for customization is from Radii Devices.

- Simulation: Utilize software tools to simulate how the prosthetic will perform under various conditions, making adjustments as necessary to ensure durability and comfort.

- Feedback Loop: Work closely with the patient and healthcare professionals to refine the prosthetic design based on feedback, ensuring it meets the user's needs and preferences.

- Software companies for 3D design: Radii Devices , Spentys , Qwadra

|

Vertical Divider

3D Printing

|

Robotic Milling

|

- Initial Fitting: Arrange a session to fit the prosthetic on the patient, evaluating its comfort, alignment, and functionality.

- Adjustments: Make any necessary adjustments. Some issues can be resolved by modifying the printed prosthetic, while others might require re-designing and reprinting.

- Training and Rehabilitation: Provide training on using the prosthetic, which might include physical therapy or exercises to improve comfort and functionality. Collect feedback for any further refinements

- Regular Check-Ups: Schedule follow-up appointments to monitor the patient's adaptation to the prosthetic, addressing any wear and tear or changes in the patient's condition.

- Reassessments: Reassess the fit and functionality of the prosthetic periodically, especially for growing children or changing needs, to determine if new scans and adjustments are necessary.

EinScan H2 SDK

https://github.com/Shining3D/H1.2SDK

Your browser does not support viewing this document. Click here to download the document.