eviXscan3D FinePrecisionFinePrecision with Robotic Arm

|

Vertical Divider

| ||||||||||

Scan small objects with high accuracy and speed

A tiny scanner with great possibilities

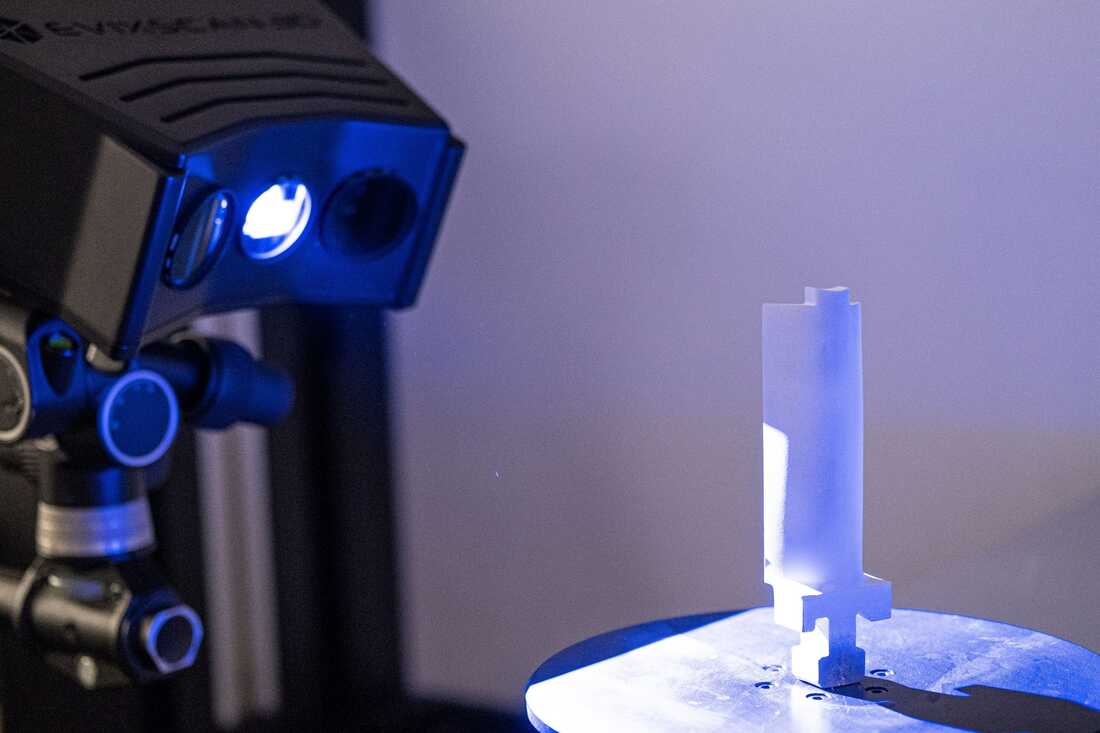

The eviXscan 3D FinePrecision scanner is a device based on the latest generation of high-speed cameras with CMOS sensors and a LED blue light source - the combination of both technologies allows for very accurate reproduction of the scanned surface (accuracy <8 µm, resolution 33 µm), even with dark-surface objects. Perfect as a measuring tool for precision mechanics, especially in areas such as: production of turbine blades, microcircuits, small injection parts, as well as precise numerically processed parts. FinePrecision is also used in scanning implants, in prosthetics, as well as in the watchmaking and jewelry industry.

Precision 3D scanning in the smallest detail

FinePrecision is an optical measuring device that can be used to collect more than 1200 points per square millimeter of scanned area. A single scan gives the possibility to acquire data in the volume of 120 x 60 x 45 mm3. Thanks to the blue structured light scanning technology the noise on the scans due to ambient light can be significantly minimized. The combination of a new generation of high-speed cameras with the fast frame collection triggered by the projection system allows to reduce the scanning time below 1 second.

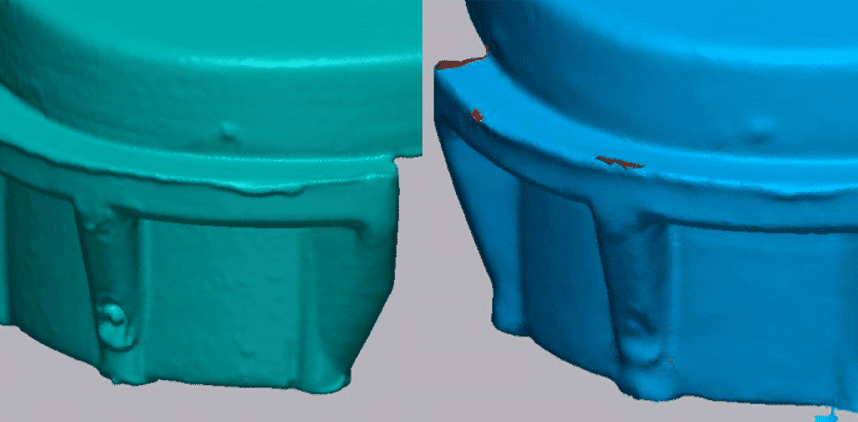

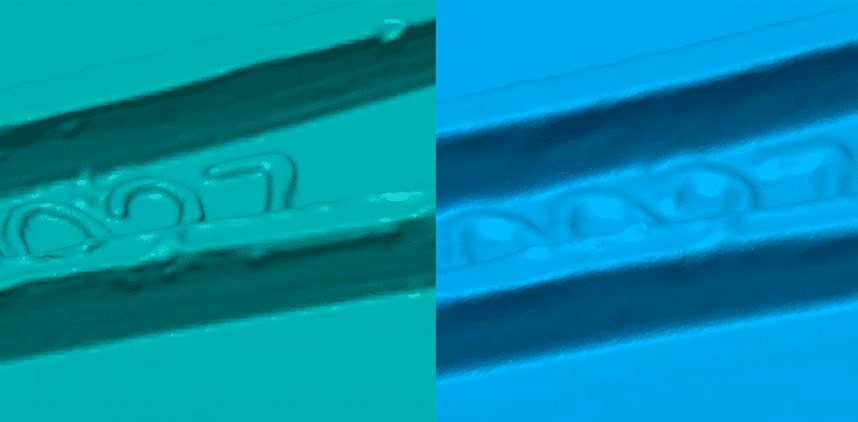

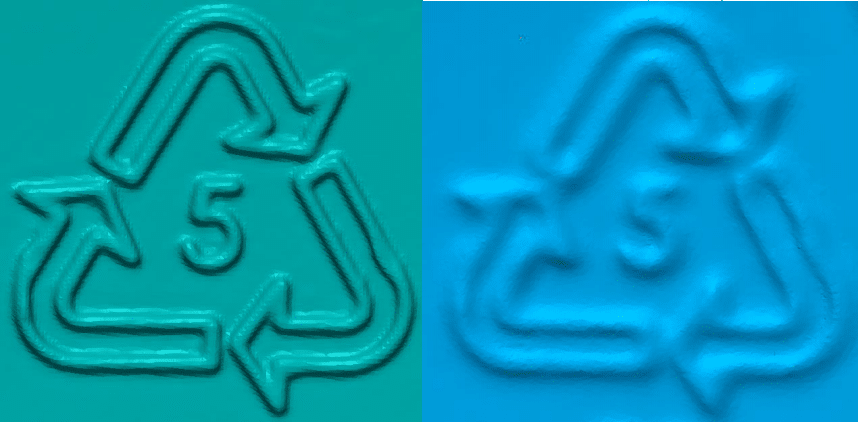

Comparison of the details of scans (left: FinePrecision, right: eviXscan 3D scanner with a different design):

The eviXscan 3D FinePrecision scanner is a device based on the latest generation of high-speed cameras with CMOS sensors and a LED blue light source - the combination of both technologies allows for very accurate reproduction of the scanned surface (accuracy <8 µm, resolution 33 µm), even with dark-surface objects. Perfect as a measuring tool for precision mechanics, especially in areas such as: production of turbine blades, microcircuits, small injection parts, as well as precise numerically processed parts. FinePrecision is also used in scanning implants, in prosthetics, as well as in the watchmaking and jewelry industry.

Precision 3D scanning in the smallest detail

FinePrecision is an optical measuring device that can be used to collect more than 1200 points per square millimeter of scanned area. A single scan gives the possibility to acquire data in the volume of 120 x 60 x 45 mm3. Thanks to the blue structured light scanning technology the noise on the scans due to ambient light can be significantly minimized. The combination of a new generation of high-speed cameras with the fast frame collection triggered by the projection system allows to reduce the scanning time below 1 second.

Comparison of the details of scans (left: FinePrecision, right: eviXscan 3D scanner with a different design):

|

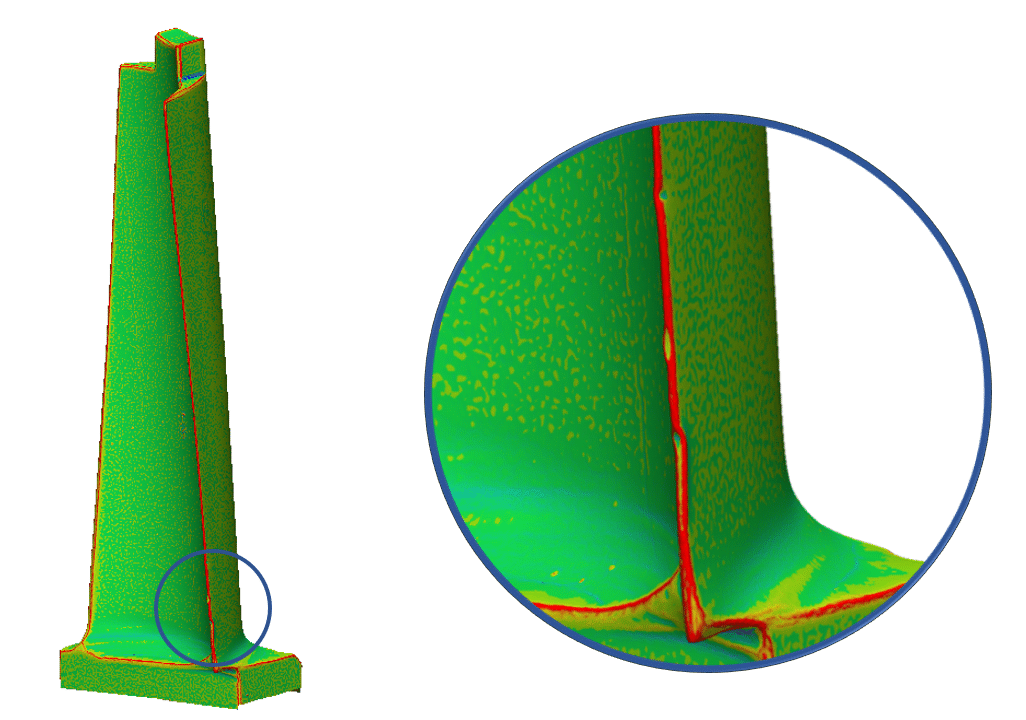

High-quality scans of the sharp edge of an object

The small scanning area in combination with the high-resolution cameras allow for the creation of a scanner with an unsurpassed resolution of 0.02 mm (> 1200 points / mm2). These parameters allow the analysis of surface microdamages, dents occurring during the operation of machines and devices, as well as errors in the production process. |

|

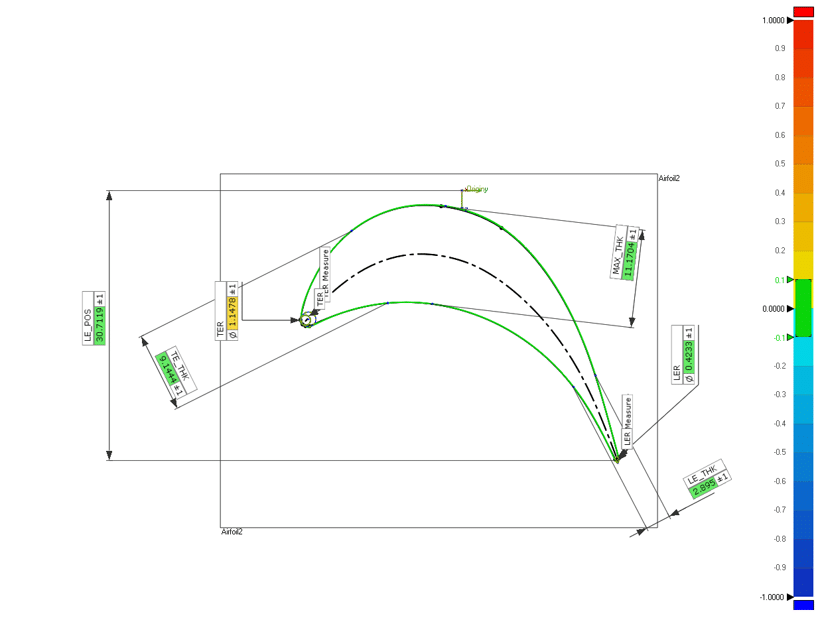

Detailed analysis of turbine blades with Geomagic Control X Control the quality of turbines, blisks, blings or blades with the included airfoil analysis tools. Control X automates the measurement of:

|

|

Vertical Divider

HIGH ACCURACY FOR SMALL OBJECTS

STANDARD CONFIGURATION

|

EVIXSCAN SOFTWARE

SUPPORT

SOFTWARE BUNDLE OPTIONS

|

Minimum System Requirement

- 32 GB RAM

- CPU i7 7th Generation

- SSD NVMe 480GB

- USB 3.0

Supported Operating System

- Standard-PC (64 bit – Windows 10)

Terms and Conditions

- Returns accepted within 30 days of purchase

- Open returns are subject to a 30% restocking fee on the condition there is no damage and the kit is returned complete with all components

- Return shipping costs are paid by the returner

|

Vertical Divider

GROWSHAPESStay connected |

Menu |

©2024 Growshapes LLC. All rights reserved.