LET'S TALK ABOUT 3D SCANNING |

|

In the ever-evolving world of watersports, efoiling has taken the spotlight with its thrilling combination of surfing and flying above water. Efoil boards, propelled by electric motors, offer an exhilarating experience, and at the heart of their performance lies the efoil wing. However, this industry is young and manufacturers struggle to survive such as FOIL Inc (getfoil.com) as there is not enough demand out there leaving enthusiasts in a lurch when their favorite wing model is no longer available to purchase and the original designs may be lost. Fortunately, 3D scanning and reverse engineering offer a lifeline for reviving these designs. In this blog post, we'll explore how you can use 3D scanning technology to bring an out-of-production foil wing back to life. Importance of the Efoil Wing The efoil wing is crucial for the lift and stability of the board, directly affecting the rider's experience. Each wing model has its unique design that caters to different riding styles, water conditions, and skill levels. When a beloved wing is no longer produced, finding a suitable replacement can be challenging, making reverse engineering an appealing solution. We have 3D scanned the efoil wing 200 of the FOIL series using the EinScan Pro HD with high accuracy as the initial step to enable full reverse engineering and manufacturing. PART I: 3D SCANNNING TO CAPTURE THE ACCURATE SIZE AND CURVATURE Step 1: Preparing for 3D Scanning Before diving into the scanning process, you'll need the right tools and a suitable environment. Here is what we used.

Step 2: 3D Scanning the Efoil Wing

Step 3: Post Processing

Here is the STL file so you can further reverse engineer and manufacture via 3D printing!

PART II: REVERSE ENGINEERING

PART III: MANUFACTURING Once satisfied with the redesigned model, it's time to manufacture the wing.

CONCLUSION 3D scanning and reverse engineering provide a powerful combination for resurrecting discontinued efoil wings. By capturing the precise geometry of a classic wing and using modern tools to refine and replicate its design, enthusiasts can continue to enjoy their favorite efoil experiences. Whether you're an efoil aficionado or a watersports innovator, this technology opens up a world of possibilities for preserving and enhancing the sport. So, don't despair about FOIL Inc going bust, let technology breathe new life into it! Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

0 Comments

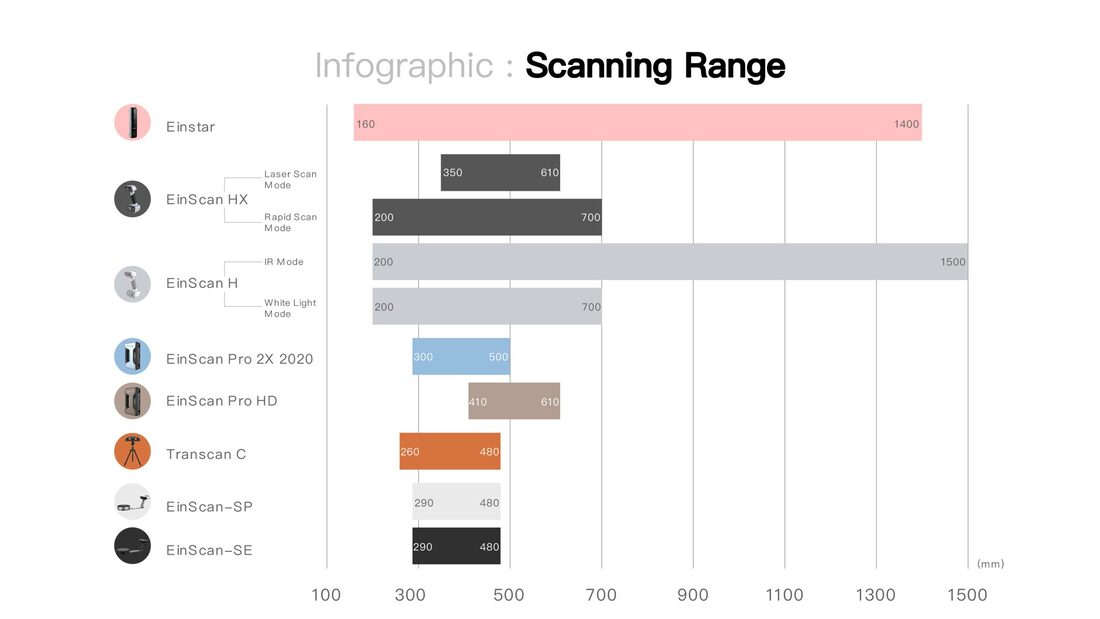

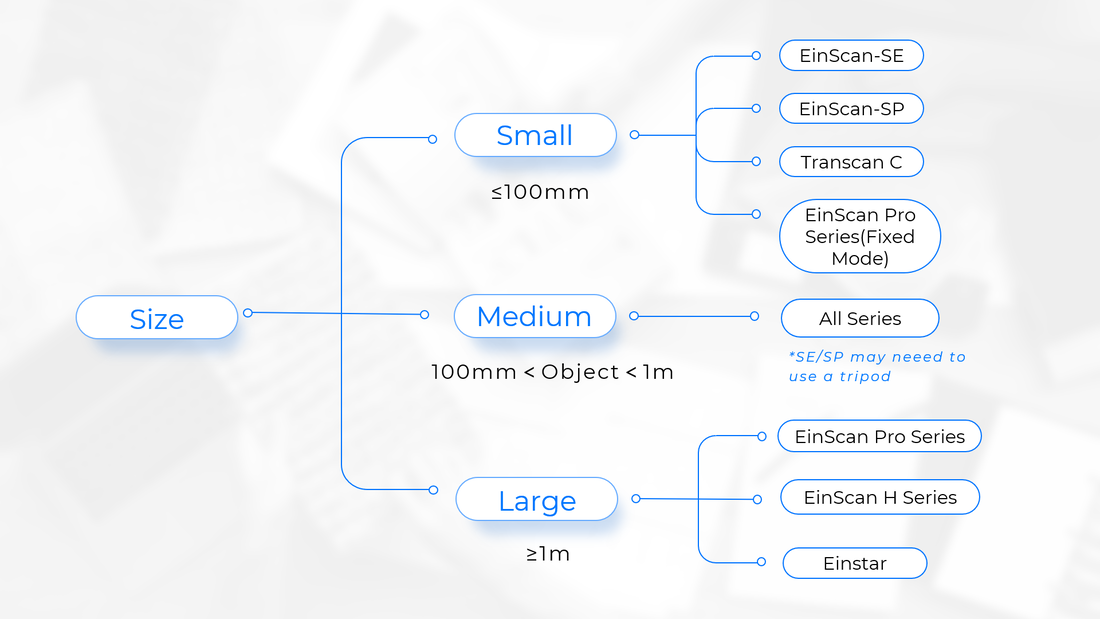

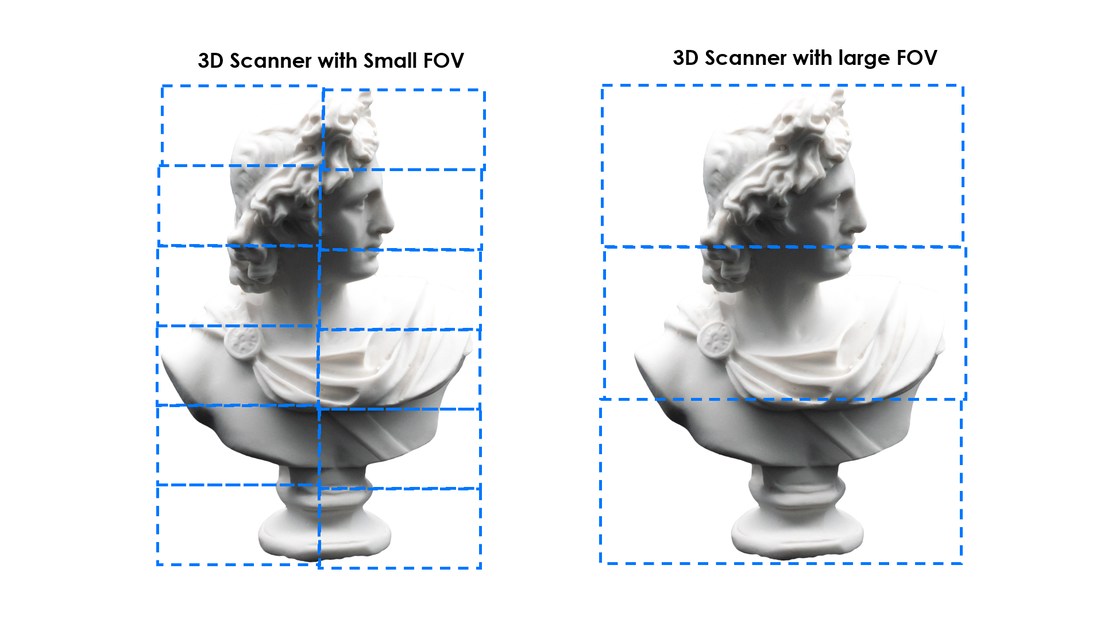

Every once in a while, it’s important to revisit the basics to understand how 3D scanners work. In this blog post, we’ll cover the Field of View (FOV) of a 3D scanner and how it affects the 3D scan results. The key takeaway is that different 3D scanners have different FOVs, and choosing the right model is crucial to getting the right output depending on the size of the object you want to 3D scan. What is Field of View (FOV)?Like how humans can see a certain range (you can't see behind you) at a given moment, different 3D scanners have a different viewable area at one time from a specific distance. The larger the FOV, the larger area the 3D scanner can 'see' thus capture at once. With the EinScan 3D scammer models, there is a variety of scanning range among different 3D scanner models that scan something as small as a coin to something as large as a car. Therefore, it is important to understand what you are scanning and what FOV is most suitable to capture the details of the object. The FOV of a 3D scanner can determine which model is best suited to 3D scan your object depending on its size. Choosing the right field of view is about finding the right balance between capturing enough detail of the object you want to scan and appropriate coverage for each scan. This balance is important so you can achieve a smoother scanning experience, complete scans in a shorter amount of time as well as reduce computer crashes that happen when the software is overloaded.

|

|||||||||||||||||||||||||||

| What happens when you use a 3D scanner with a small FOV to scan large objects? When you scan a large object with a 3D scanner optimized for scanning small objects, you will have to do more scans to reconstruct a complete 3D digital model than you would with a scanner with a large FOV. Look at the theoretical diagram on the left. If you have a large FOV, you only need 3 scans but with a small FOV you need 12 scans. In reality there are overlaps so this is just an illustration. |

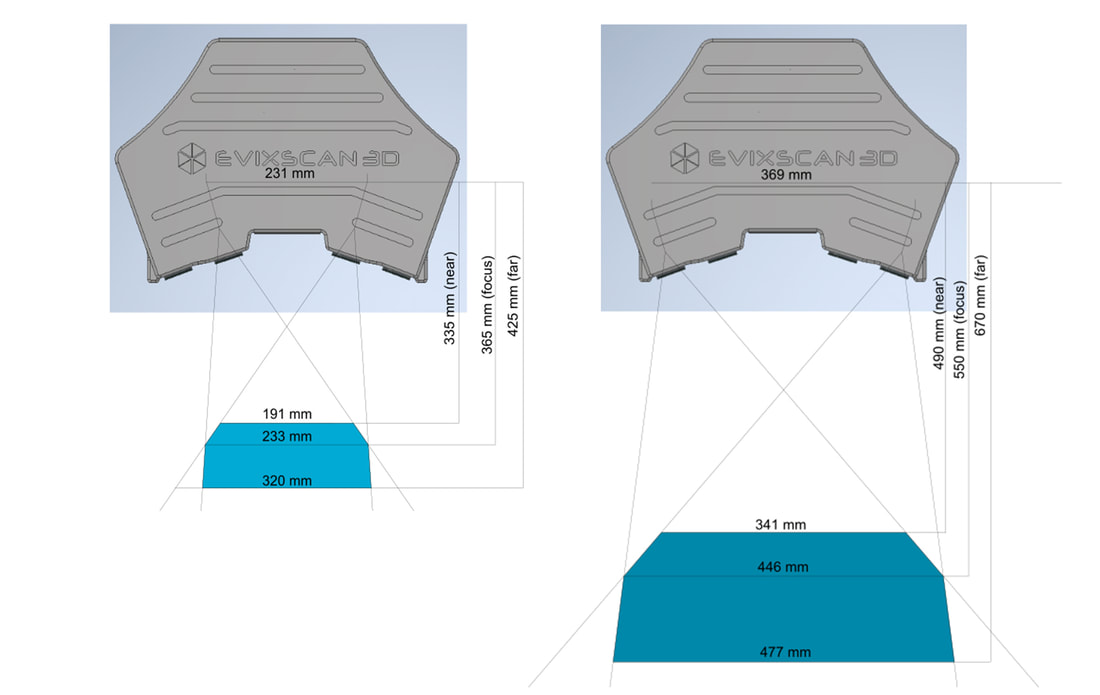

Some scanners have dual FOV like the Transcan C and the eviXscan 3D Quadro+ so it can scan small and medium size objects. On the TranScan C, you can slide the cameras out to increase the FOV, while on eviScan Quadro there are 4 cameras installed - the inner cameras and the outer cameras.

It really depends on the simplicity and versatility you require for the project. Naturally, having multiple FOV is a bit more complex due to having varying settings.

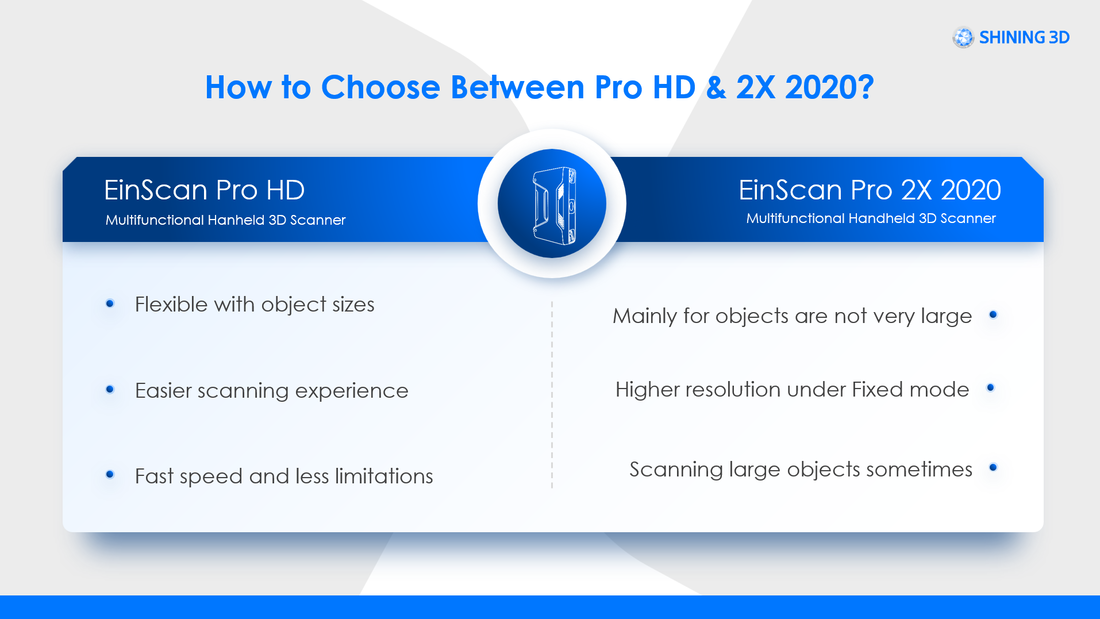

Now let's dig a little deeper and look at the difference in FOV of Einscan Pro HD vs. Einscan Pro 2X 2020.

Now let's dig a little deeper and look at the difference in FOV of Einscan Pro HD vs. Einscan Pro 2X 2020.

Comparing Einscan Pro HD vs EinScan Pro 2X 2020

You can see that these 2 scanners have a different FOV. Guess which one is better suited for large objects? You probably guessed it right if you followed the logic so far - it's the EinScan Pro HD. Objects that are not very large like within the 3-100mm range, EinScan Pro 2X 2020 is better and it's cheaper too!

So, keep in mind that there is no one-FOV-fits-all 3D scanner if you want a great 3D scanning output. The first step in choosing a 3D scanner is to confirm the size of the object you need to scan so it can help you determine the FOV of the scanner required. In the next blog, we will help you narrow it down further and together we will look at how the material on the surface of the object can affect your purchase choice.

Watch this webinar on how to select a model if you want to learn further!

Watch this webinar on how to select a model if you want to learn further!

Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

Shining 3D has come out with an affordable 3D scanner to enable 3D scanners to be used by more people to digitize our world in full color! Best suited for VR/AR applications and digital content designers for sure.

It's pretty good for a low cost 3D scanner, but ofcourse if you want more accuracy you do need to step up a notch for the higher end models.

Check out the video we created below.

It's pretty good for a low cost 3D scanner, but ofcourse if you want more accuracy you do need to step up a notch for the higher end models.

Check out the video we created below.

Also beware you do require a good GPU and lots of memory to run this 3D scanner.

Einstar

Generates high-quality 3D data in full color at an affordable price and easy to use software. Perpetual license with no ongoing subscription fees.

Approx. 0.3mm accuracy.

PC Requirement: Win 10/11 |32GB RAM | NVIDIA GTX or RTX with over 1,000 CUDA cores | Intel CPU i7 or i9

Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

In 3D scanning, accuracy is a key metric in choosing which model to use for your project.

How accurately do you need to replicate the physical model? In other words, how authentic do you want the 3D digital model of the real object to be?

High end 3D scanners like eviXscan Quadro+ can achieve up to 0.007mm (7 microns) accuracy, while lower end 3D scanners like EinScan SP can still achieve an accuracy up to 0.05mm (50 microns). Accuracy of a 3D scanner depends on the quality of the camera, projector lights as well as the software.

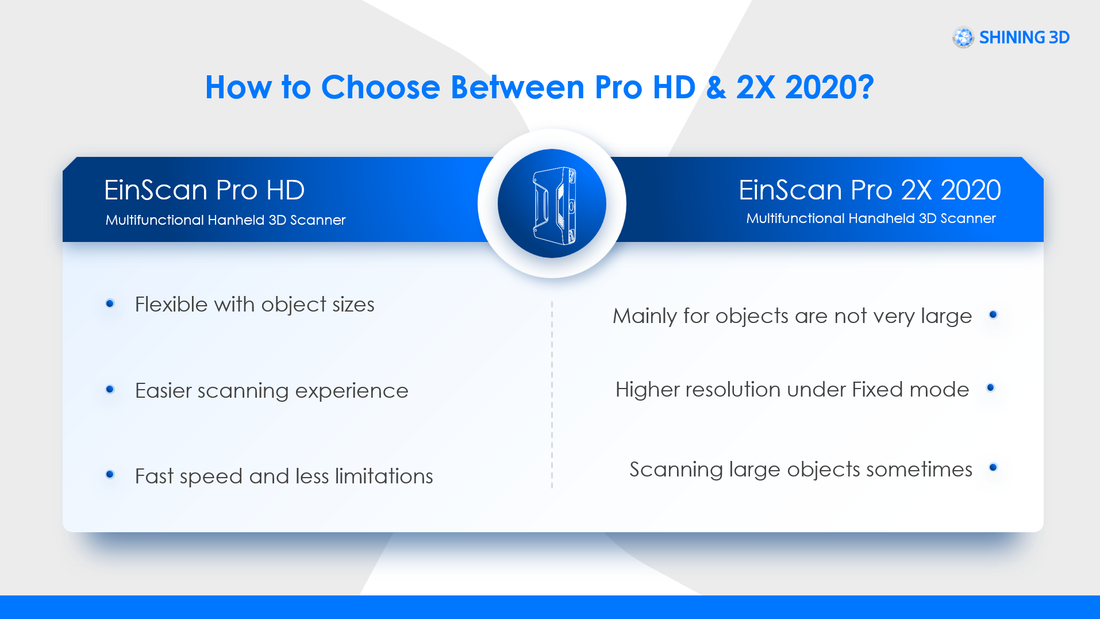

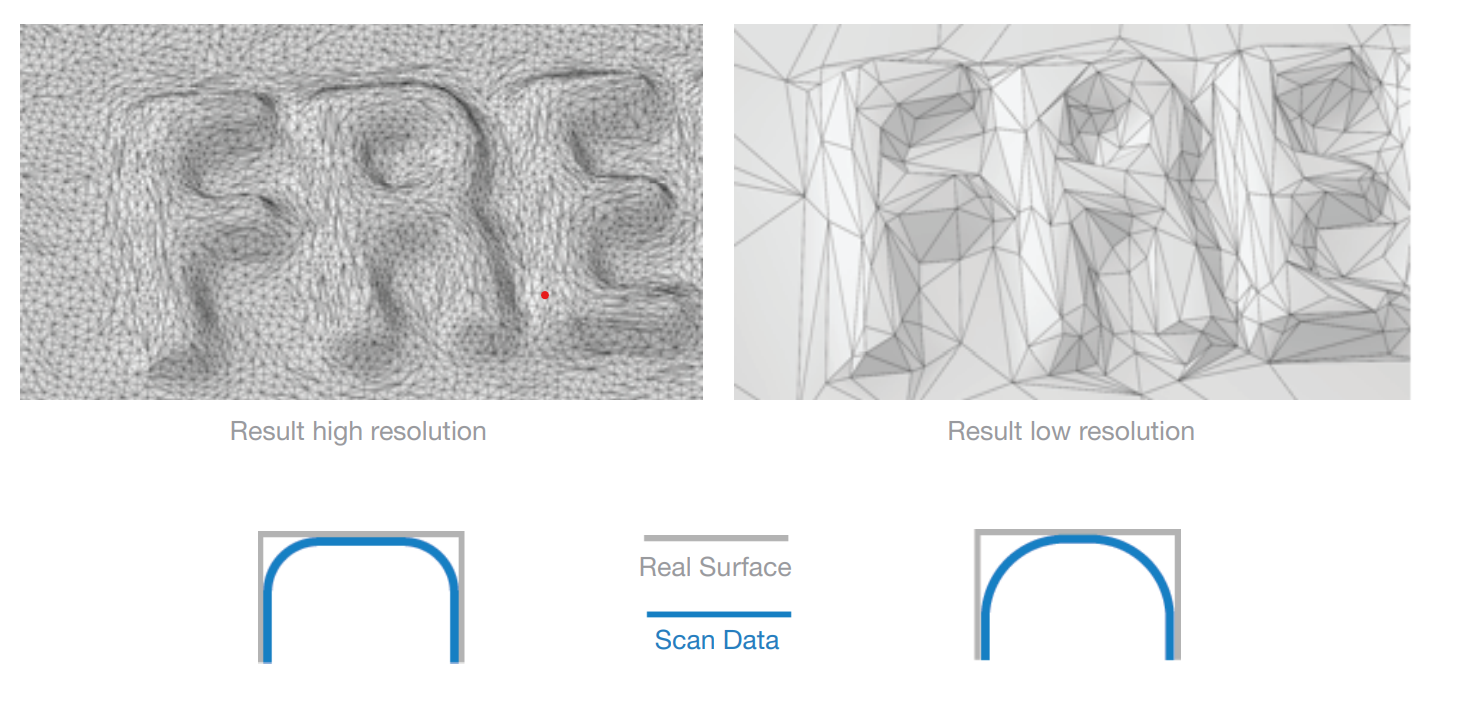

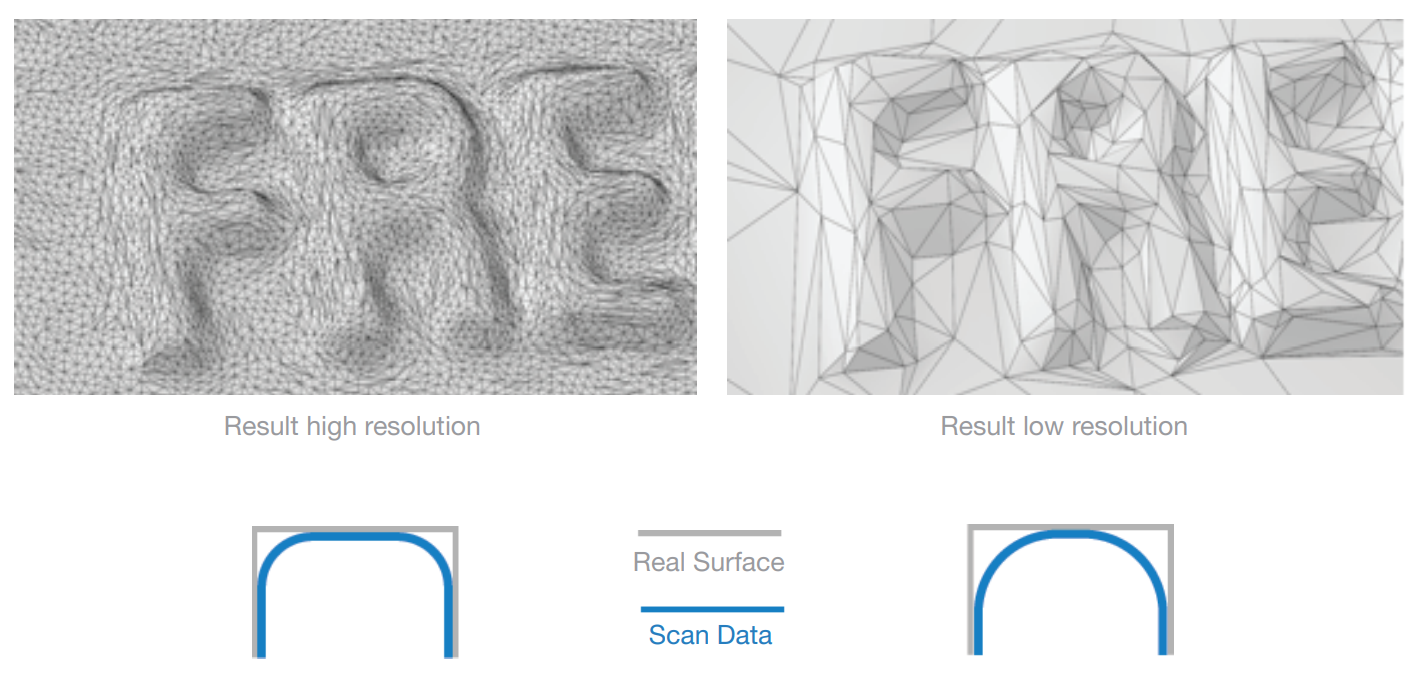

Meanwhile there is another important metric, resolution. Resolution is about defining the point distance the 3D scanner can capture to generate the point cloud which is then converted into a mesh. If you 3D scan your object in high resolution, the point distance is small thus details will be more visible, while if you 3D scan your object in low resolution, the point distance is bigger.

How accurately do you need to replicate the physical model? In other words, how authentic do you want the 3D digital model of the real object to be?

High end 3D scanners like eviXscan Quadro+ can achieve up to 0.007mm (7 microns) accuracy, while lower end 3D scanners like EinScan SP can still achieve an accuracy up to 0.05mm (50 microns). Accuracy of a 3D scanner depends on the quality of the camera, projector lights as well as the software.

Meanwhile there is another important metric, resolution. Resolution is about defining the point distance the 3D scanner can capture to generate the point cloud which is then converted into a mesh. If you 3D scan your object in high resolution, the point distance is small thus details will be more visible, while if you 3D scan your object in low resolution, the point distance is bigger.

| With EinScan 3D scanners, you can set the resolution you want to 3D scan at depending on your target object. Some key things to remember when selecting the correct resolution are below:

|

Below is a guideline of resolution settings that is optimal depending on the type of objects you are 3D scanning. Basically the recommendation is the smaller the object, use high detail (higher resolution) and the larger the object, use low detail (lower resolution) settting.

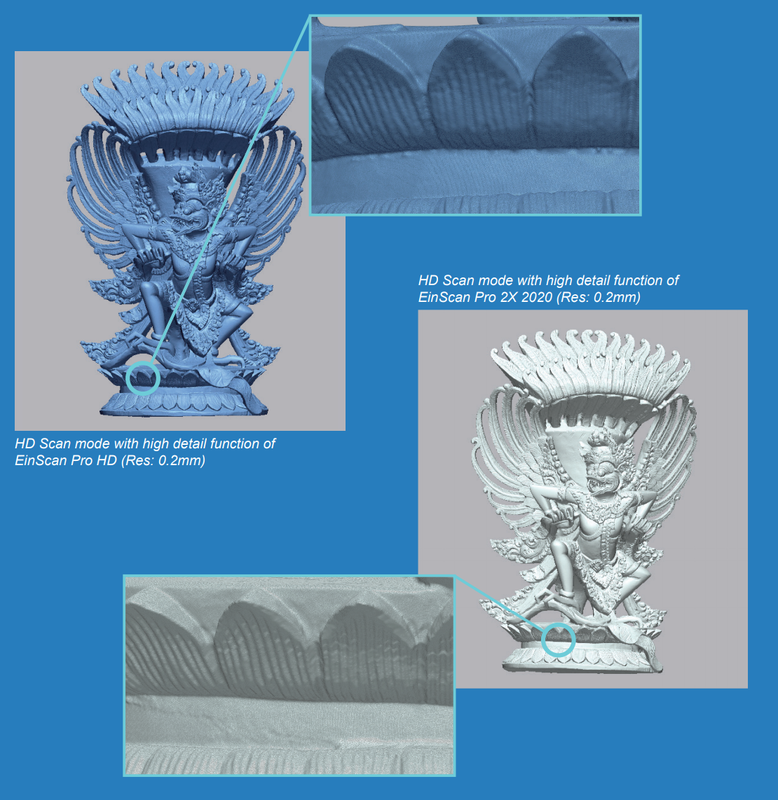

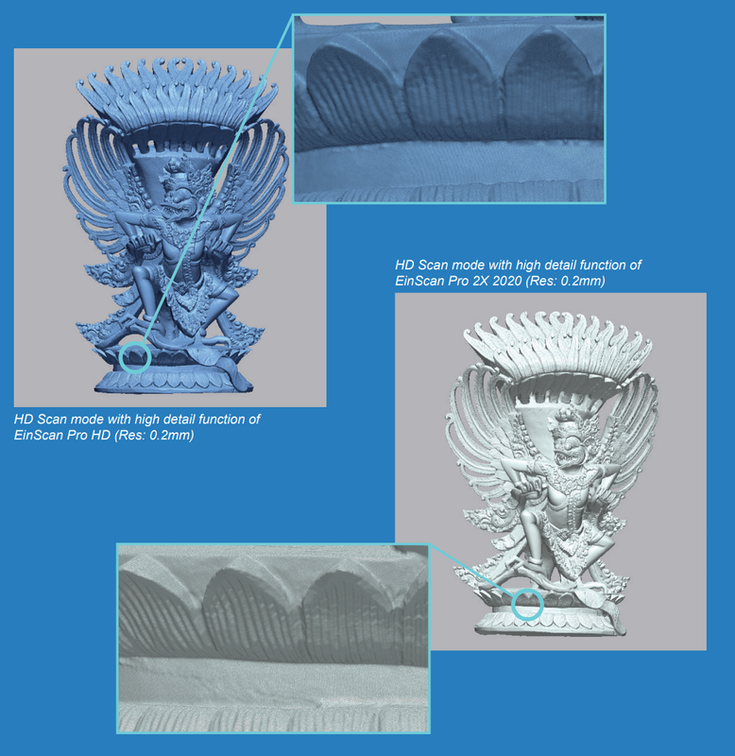

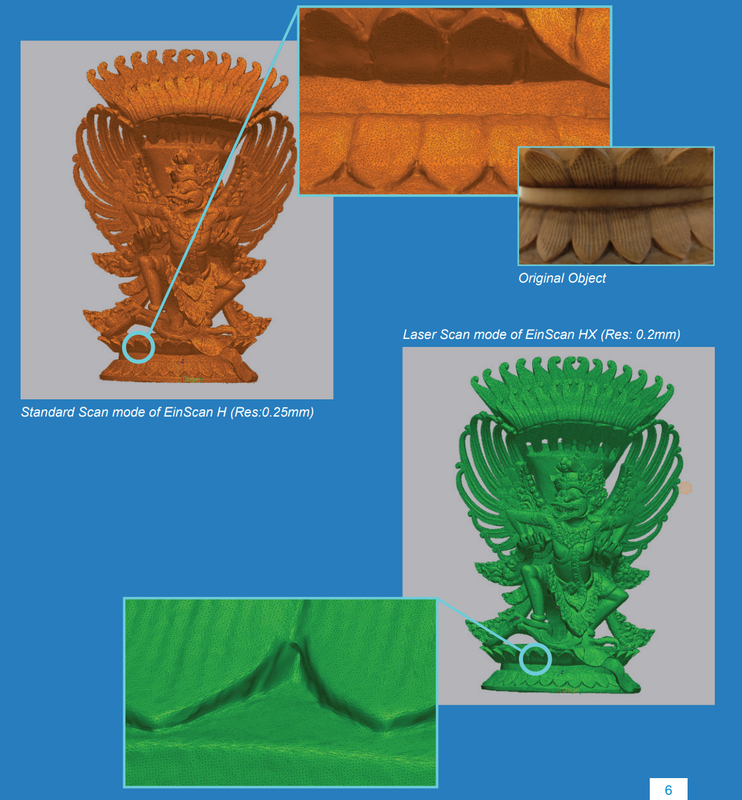

The Einscan Pro HD and EinScan 2X 2020 provde super high resolution with HD scan mode and setting the resolution to "High Detail". This kind of high detail captures is useful for objects with that has a lot of details like the object below. On the other hand, large engineering parts may not require such detail but higher accuracy.

Basically the tip is to think about what you are going to do about your 3D scan file and choose the right resolution setting depending on the object you are 3D scanning.

Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

Alignment is an important step for 3D scanning to ensure the 360 degree digital surface model generated by the 3D scanner accuractly replicates the physical object.

With Shining 3D scanners, there are several alignment methods that can be deployed, depending on the shape of the target object. Let's go through them one by one.

With Shining 3D scanners, there are several alignment methods that can be deployed, depending on the shape of the target object. Let's go through them one by one.

|

1. Coded Target Alignment

This method uses the coded target on the turntable when used with the EinScan SE, EinScan SP, EinScan Pro 2X & Einscan Pro HD. For this method there are 2 things to remember:

|

Vertical Divider

|

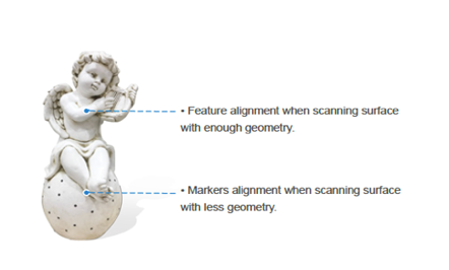

2. Feature Alignment

|

Vertical Divider

This method uses the features of the target object to align, thus most suitable for organic shapes or objects with a lot of features.

This alignment method does not work with objects that have planar surfaces or objects that are symmetric, i.e. mechanical parts. |

3. Markers Alignment

4. Texture Alignment

5. Hybrid Alignment

|

This method is best suited for objects that have a combination of organic shape and non-organic form like this statue. The 3D scanner will switch between the feature and the marker tracking during the scan process. Markers are only needed with a surface that has less geometry. The scanning speed will be slower, however. |

Vertical Divider

|

Also important to remember is when you are 3D scanning a large object on a tripod without a turntable, you need to ensure there is at least a 30% overlap from one scan to the next to ensure alignment.

So that's it. Not as difficult as you thought, right?

Growshapes the official U.S. distributor of Shining 3D EinScan 3D scanners. We now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

We get asked this question a lot. That's why we are here to help. It's not easy to choose a 3D scanner that needs to capture different sizes, surfaces, shapes and textures. It also depends on your budget. The difference in price comes from different components such as the camera lens, projector, light source, and software complexity.

Let's outline 4 important features you need to understand to decide which model would be most suited for your project.

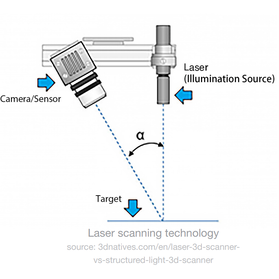

1. Light Source - Structured Light Or Laser?

Let's outline 4 important features you need to understand to decide which model would be most suited for your project.

1. Light Source - Structured Light Or Laser?

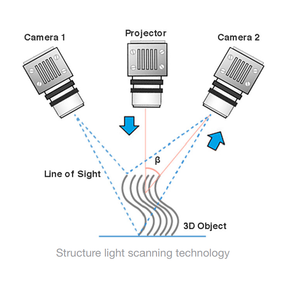

| Structured Light 3D Scanners Structured Light 3D scanners project a light pattterns onto the target object. The changes in the variance in the light patterns are tracked by the cameras and the software algorithm generates point clouds to capture the 3D surface. The structured light pattern projection allows the 3D scanner to captuer a large dimension in seconds in high resolution. Structured light is not hazardous to eyesight. It best performs in an environment where the light condition is stable. There are white light and blue light structured light 3D scanners. Blue light has a narrower wavelength where as white light is a combination of all the colors in the visible spectrum. The narrow wavelength enables better filtering of the interference of ambient light thus offers better precision, accuracy and higher quality outputs. |

| Laser 3D Scanners Laser scanner projects a laser point or beams onto the target object and the reflection of the laser light is captured with the sensors. Laser light is less sensitive to environmental light and performs better in capturing shiny or dark surfaces. However, very shiny or transparent surfaces are still difficult to capture by laser light. |

2. Accuracy and Resolution

Accuracy

The accuracy gives an information about the authenticity of a 3D model to the real object. Knowing the accuracy of your scanner is very important because it determines which model is most suitable for quality inspection, reverse engineering design, medical health, or any other applications with very rigid accuracy requirements. Usually, the higher accuracy the scanner is able to generate, the more applications it could be suitable for, and of course, the higher the cost.

Remember though, not all 3D scanning projects require the highest accuracy, so consider your budget and requirements to make a decision on which model to purchase. The accuracy used in the specifications of the scanner usually refer to the accuracy of a single scan. The volumetric accuracy refers to the relationship between 3D data accuracy and object size; with EinScan Pro Series the accuracy is reduced by 0.3mm per meter. This data is based on measuring the center of sphere with marker alignment. The volumetric accuracy of EinScan HX in laser mode is 0.06 mm per meter.

The accuracy gives an information about the authenticity of a 3D model to the real object. Knowing the accuracy of your scanner is very important because it determines which model is most suitable for quality inspection, reverse engineering design, medical health, or any other applications with very rigid accuracy requirements. Usually, the higher accuracy the scanner is able to generate, the more applications it could be suitable for, and of course, the higher the cost.

Remember though, not all 3D scanning projects require the highest accuracy, so consider your budget and requirements to make a decision on which model to purchase. The accuracy used in the specifications of the scanner usually refer to the accuracy of a single scan. The volumetric accuracy refers to the relationship between 3D data accuracy and object size; with EinScan Pro Series the accuracy is reduced by 0.3mm per meter. This data is based on measuring the center of sphere with marker alignment. The volumetric accuracy of EinScan HX in laser mode is 0.06 mm per meter.

| Resolution Resolution defines the point distance of the points within the point cloud the 3D scanner is capturing. The distance between two points in a 3D model is one of the most important factors for your scan. When you take a high resolution, the point distance is very small, and details are better to see on the scan. If you capture in low resolution, the point distance is big and big objects can be captured faster and the 3D scan data file size will be smaller. |

With EinScan handheld 3D Scanners the Pro Series and the H series, the resolution can be changed depending on the object size to ensure the 3D scan data size is manageable.

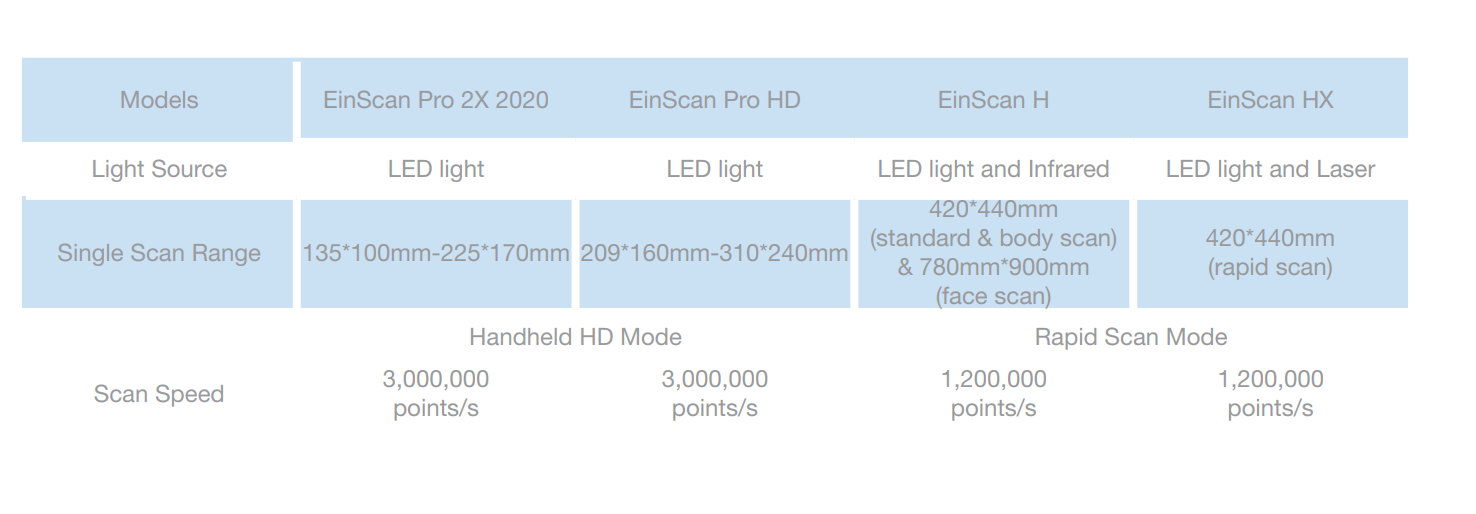

3. Scan Speed

Scan speed is a specification that definese how long it takes to scan one given object. It especially matters when you are going to scan the human body, as people can not stay still for a long time, and it also helps to improve the work efficiency when you are 3D scanning large objects like cars, buildings, etc. Scan speed can be defined by the number of points collected per second, frames per second, or how many seconds it takes to do a single scan. The more points or frames collected per second, the faster the scan speed.

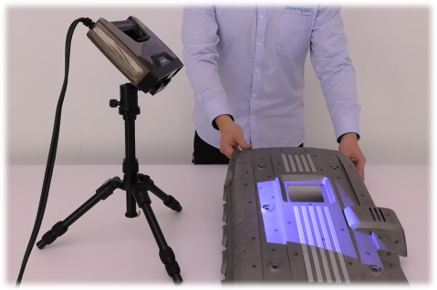

4. Desktop or Handheld

Desktop 3D scanners are provides higher accuracy and enables automation of the whole 3D scan process. The EinScan Pro series handheld 3D scanners can be turned into a desktop/fixed 3D scanners with the Industrial Kit. For 3D scanning larger objects (like humans or cars), using the handheld 3D scanner is the only solution.

Scan speed is a specification that definese how long it takes to scan one given object. It especially matters when you are going to scan the human body, as people can not stay still for a long time, and it also helps to improve the work efficiency when you are 3D scanning large objects like cars, buildings, etc. Scan speed can be defined by the number of points collected per second, frames per second, or how many seconds it takes to do a single scan. The more points or frames collected per second, the faster the scan speed.

4. Desktop or Handheld

Desktop 3D scanners are provides higher accuracy and enables automation of the whole 3D scan process. The EinScan Pro series handheld 3D scanners can be turned into a desktop/fixed 3D scanners with the Industrial Kit. For 3D scanning larger objects (like humans or cars), using the handheld 3D scanner is the only solution.

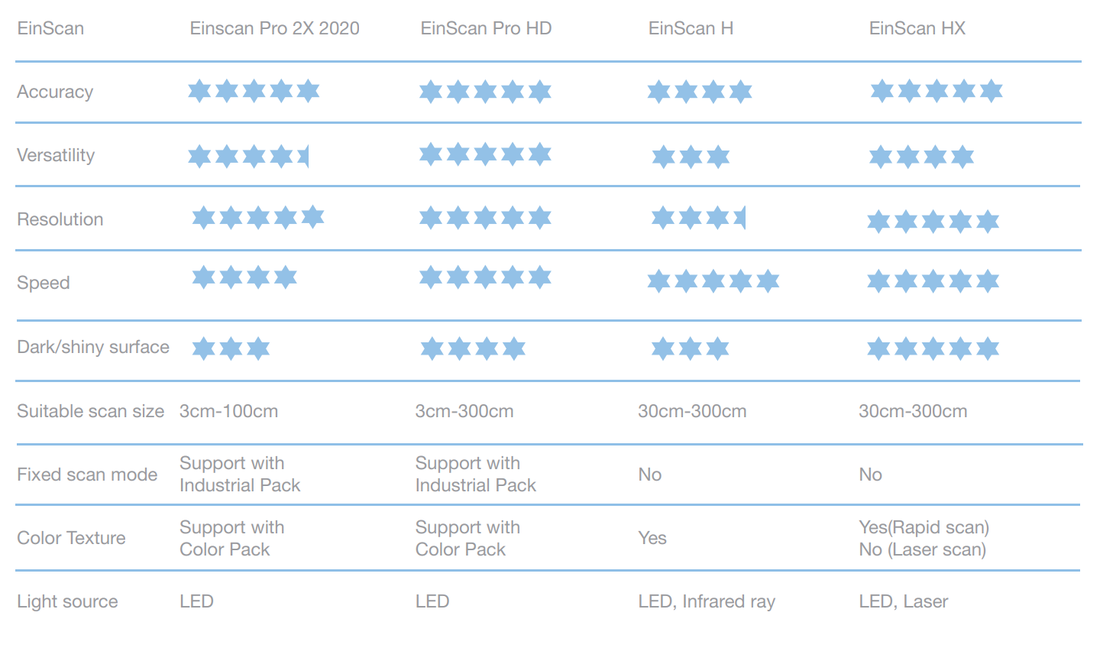

So which model shall I buy?

- For smaller objects, definitely the EinScan Pro 2X 2020 (white structured light) to achieve high resolution and high quality 3D modeling and design.

- For mid-large size objects and with higher accuracy and resolution either the EinScan Pro HD (white structured light) or the EinScan HX (laser & blue light).

- If you want versatility and also want to automate the 3D scanning workflow, go for the EinScan Pro HD with Industrial Kit. The new projection hardware and software algorithm allows the EinScan Pro HD to scan dark and casting metal surfaces.

- If you have very shiny or dark surfaces, go for the EinScan HX. The laser scanning mode guarantees outstanding accuracy and resolution.

- If you want to capture people or furniture with color texture, EinScan H (infrared & white light) is the way to go. It captures hair and also has a special body scan mode which facilitates data acquisition despite slight movements.

Here is a comparison at a glance.

Accuracy Comparison

In reality all of the above models have similar accuracies.

EinScan Pro HD and EinScan Pro 2X 2020 both have the same accuracy of 0.045mm in Handheld HD mode, while it is 0.05mm for EinScan H in body and standard mode, and 0.04mm for EinScan HX in laser mode. So accuracy might not be a critical parameter for you to choose a proper device among EinScan series. If high accuracy is a top priority on your agenda, EinScan HX is the best choice among all EinScan scanners.

In reality all of the above models have similar accuracies.

EinScan Pro HD and EinScan Pro 2X 2020 both have the same accuracy of 0.045mm in Handheld HD mode, while it is 0.05mm for EinScan H in body and standard mode, and 0.04mm for EinScan HX in laser mode. So accuracy might not be a critical parameter for you to choose a proper device among EinScan series. If high accuracy is a top priority on your agenda, EinScan HX is the best choice among all EinScan scanners.

Resolution Comparison

EinScan Pro Series (2X 2020 & HD) achieves a higher resolution compared to EinScan H series. Resolution captured by EinScan Pro 2X 2020 is marginally higher than the Pro HD due to the single scan range being smaller.

EinScan Pro Series (2X 2020 & HD) achieves a higher resolution compared to EinScan H series. Resolution captured by EinScan Pro 2X 2020 is marginally higher than the Pro HD due to the single scan range being smaller.

The EinScan H series have a different projecting pattern to the Pro Series thus the resolution is lower. But remember, the EinScan HX can achieve a higher accuracy vs. the Pro Series.

Scan Speed Comparison

To compare the speed of scanners, two facts need to be considered: single scan range and the points captured per second.

For points captured per second, in Handheld Rapid mode, all scanners of the EinScan Pro Series come with the same speed of 1,500,000 points/s. However as the EinScan Pro HD has a larger single scan range, it can scan large objects at a faster speed. EinScan H (standard scan&body scan) and EinScan-HX (rapid scan) come with the same scan speed in terms of points captured per second and scan range, which are all faster than Pro series. In the face scan mode of EinScan-H, the maximum scan range could reach 780mmx 900mm enabling a fast scan.

For points captured per second, in Handheld Rapid mode, all scanners of the EinScan Pro Series come with the same speed of 1,500,000 points/s. However as the EinScan Pro HD has a larger single scan range, it can scan large objects at a faster speed. EinScan H (standard scan&body scan) and EinScan-HX (rapid scan) come with the same scan speed in terms of points captured per second and scan range, which are all faster than Pro series. In the face scan mode of EinScan-H, the maximum scan range could reach 780mmx 900mm enabling a fast scan.

Hope this answers many of the questions you may have had!

Growshapes is an HP Silver Partner of HP 3D scanning solutions and the official U.S. distributor of Shining 3D EinScan 3D scanners. We are now carry the eviXscan 3D scanner from Evatronix as well!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D.

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D.

EinScan H

The new EinScan H combines Infrared & LED in one unit, tailored to 3D scanning human face & body scanning as well as large objects with color texture.

The new EinScan H combines Infrared & LED in one unit, tailored to 3D scanning human face & body scanning as well as large objects with color texture.

EinScan HX

The new EinScan HX combines blue laser and blue light in one unit that enables 3D scanning of reflective and dark surfaces with high accuracy.

Growshapes is an HP Silver Partner of HP 3D scanning solutions and the official U.S. distributor of Shining 3D EinScan 3D scanners. We are now carrying the eviXscan 3D scanner from Evatronix too!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D.

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D.

Evatronix, the industrial-grade 3D scanner manufacturer, is shipping two new 3D scanner models early March 2020 to the USA! Announced at Formnext 2019, these 2 new scanners utilize the advanced eviXscan 3D scanning software that comes with Heavy Duty Optima and Heavy Duty Quadro, while it is optimized to scan larger objects and smaller objects with high precision.

Both the Wide Range 3D scanner and the Fine Precision 3D scanners use blue LED as a light source and comes equipped with two 12 megapixel cameras. See more details in the below leaflets.

| | |

Growshapes is an HP Silver Partner of HP 3D scanning solutions and the official U.S. distributor of Shining 3D EinScan 3D scanners. We are now carrying the eviXscan 3D scanner from Evatronix too!

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D.

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D.

Growshapes had a great 2018 and have been busy to make sure we offer the best customer experience when somebody is looking to buy 3D scanners or adopt 3D scanning technology into their workflow.

Highlight of 2018

But the year isn't over yet!

If you want to add 3D scanning to your workflow, check out the 3D scanner selection on www.growshapes.com.

Highlight of 2018

- Expanded our product portfolio beyond HP 3D scanners and added Open Technologies (now FARO) industrial grade 3D scanners as well as Shining3D EinScan handheld 3D scanners

- Became a referral agent to Artec 3D scanners

- Partnered with "medifacturing" startup, PrinterPrezz, to extend reach into the medical industry with 3D scanning technology

But the year isn't over yet!

If you want to add 3D scanning to your workflow, check out the 3D scanner selection on www.growshapes.com.

We just wanted to say "thank you" for being our customer and buying 3D scanners from Growshapes!

We continue to add select 3D scanners based on structured light technology this year. We have now updated our website with the addition of Shining 3D EinScan 3D scanners including the latest and greatest EinScan Pro 2X and EinScan Pro 2X Plus (bigger scan range vs. 2X) . These 2 new models were announced at Formnext 2018 in Germany this month. Prices start from $5,499.

Key to note on EinScan Pro 2X Series:

So if you were thinking of getting a versatile handheld 3D scanner, check out the new EinScan 3D scanners!

We continue to add select 3D scanners based on structured light technology this year. We have now updated our website with the addition of Shining 3D EinScan 3D scanners including the latest and greatest EinScan Pro 2X and EinScan Pro 2X Plus (bigger scan range vs. 2X) . These 2 new models were announced at Formnext 2018 in Germany this month. Prices start from $5,499.

Key to note on EinScan Pro 2X Series:

- Improved UI: Post scan resolution setting option during data processing for faster scanning

- Faster scan speed: Processes up to 1,500,000 points per second (30 fps) under Handheld Rapid Scan Mode (Pro 2X series has 4 scan modes, same as the Pro models)

- High Speed Data Transmission: USB 3.0

- High Accuracy: Single scan accuracy under Fixed Scan/Auto Scan Mode is up to 0.04 mm

- Includes the Solid Edge SHINING 3D Edition software. Created from the collaboration between Siemens PLM Software and SHINING 3D, this software includes reverse engineering, generative design, and simulation together with CAD tool in one platform

So if you were thinking of getting a versatile handheld 3D scanner, check out the new EinScan 3D scanners!

Growshapes is an HP Silver Partner of HP 3D scanning solutions and the official U.S. distributor of Open Technologies 3D Scanners - an endorsement that makes us proud. We are adding the Shining 3D EinScan 3D scanners to our line up too.

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

See the innovators on Growshapes’ social media channels to get the latest expert news on innovation in 3D digitization, then share your thoughts and join the conversation about 3D digital innovation with #digitize3D

Growshapes

Provider of leading edge 3D scanning products and services. We see 3D!

Archives

July 2024

June 2024

May 2024

March 2024

December 2023

October 2023

June 2023

April 2023

February 2023

October 2022

September 2022

August 2022

May 2022

April 2022

March 2022

February 2022

November 2021

October 2021

August 2021

April 2021

March 2021

January 2021

December 2020

November 2020

September 2020

August 2020

June 2020

April 2020

March 2020

January 2020

December 2019

November 2019

October 2019

June 2019

May 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

November 2017

October 2017

September 2017

August 2017

July 2017

April 2017

February 2017

January 2017

December 2016

November 2016

October 2016

July 2016

June 2016

May 2016

April 2016

January 2016

December 2015

November 2015

October 2015

September 2015

July 2015

June 2015

April 2015

March 2015

January 2015

December 2014

November 2014

October 2014

September 2014

August 2014

July 2014

June 2014

May 2014

April 2014

March 2014

February 2014

January 2014

Categories

All

3D Printing

3D Scan File Ouput

3D Scanner Rental

3D Scanner Setup

3D Scanning

3D Scanning Colorful Objects

3D Scanning Dark Surfaces

3D Scanning Faces

3D Scanning Highly Details Objects

3D Scanning Humans

3D Scanning Large Objects

3D Scanning Shiny Surfaces

3D Scanning Small Objects

3D Visualization

Additive Manufacturing

Afinia

Alignment In 3D Scanning

Augumented Reality (AR)

Blue Laser

Blue Light

DAVID 3D Scanners

Design

Desktop 3D Printers

Ecology/Sustainable

Education

EFoil Wing

EinScan 3D Scanners

EinScan 3D Scanner Software

Einscan H

EinScan H2

EinScan HX

EinScan Pro 2X

EinScan Pro 2X 2020

EinScan Pro 2X Plus

EinScan Pro HD

EinScan SE/SP

Einstar

Engineering

Evatronix EviXscan

Field Of View

FormLabs

Geomagic

HP Structured Light Scanner Pro S3

Industrial Kit

Infrared

Laser 3D Scanning

MacOS

Makerbot

Makerspace

Market SIze

Mcor IRIS 3D Printer

Medical

Mesh Optimization

Netfabb Software

Open Technologies Cronos 3D Scanner

Orthotics And Prosthetics

Product Developers

Prototyping

Reverse Engineering

Shining3D

Software Updates

Solid Edge Software

Structured Light 3D Scanning

Transcan C

White Light

Workforce Development

|

Vertical Divider

GROWSHAPESStay connected |

Menu |

©2024 Growshapes LLC. All rights reserved.

RSS Feed

RSS Feed